Can you make compatible bricks with consumer 3D printers?

Posted by Huw,

My recent article concerning finding 3D printing filaments that match LEGO colours prompted some of you to question whether it's possible to print compatible bricks at home and, if so, where to get the design files.

This article aims to answer those questions.

Tl;dr: it's certainly possible, but...

Design files for LEGO parts

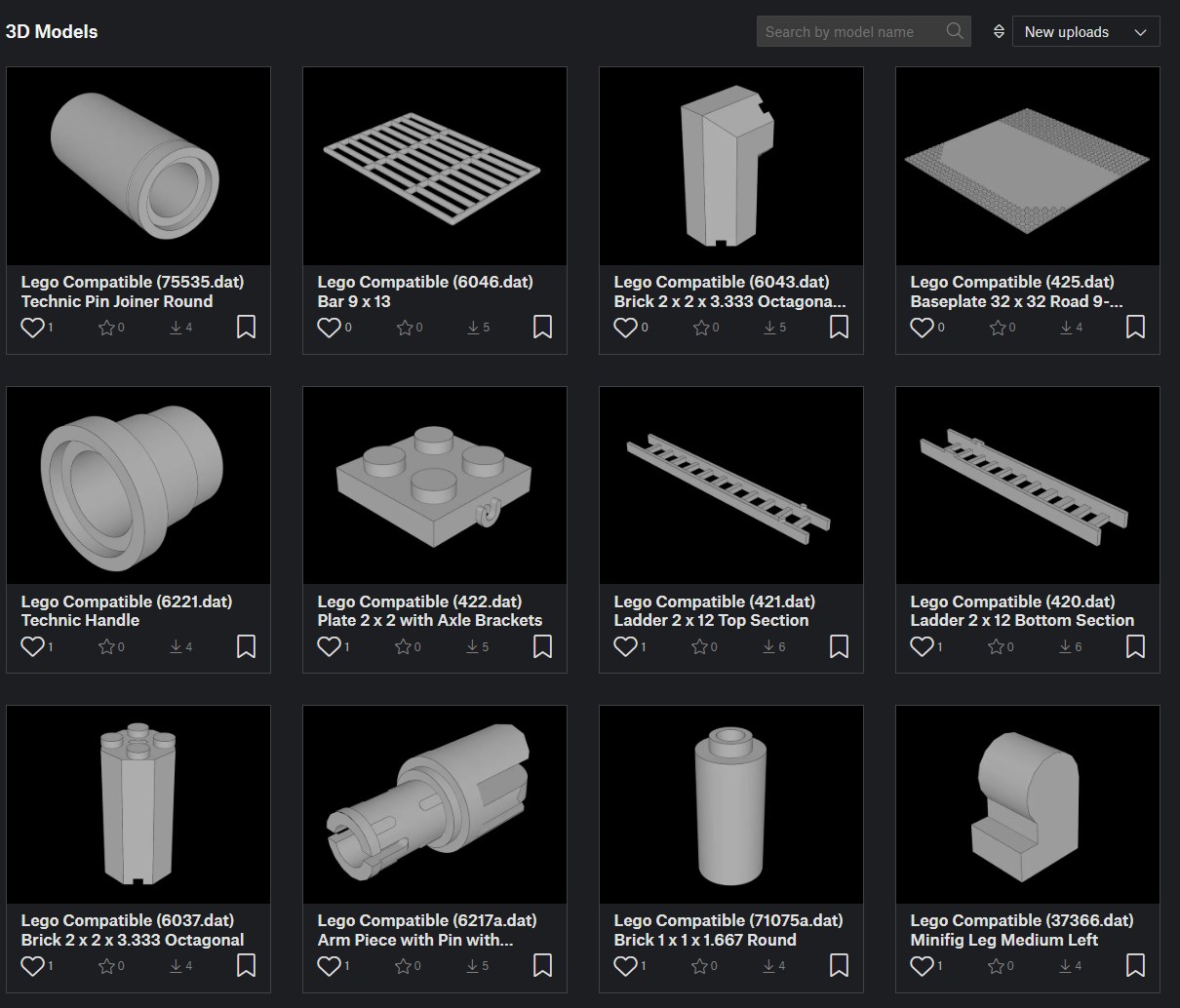

The most common file format for describing 3D objects is STL. There are many places to find STLs for LEGO pieces and a quick search at Printables, Thingiverse or Makerworld will surface them. The best repository I have found is a library for over 2,000 parts on Printables maintained by user thall72, which includes most common pieces, and he continues to add to it.

MecaBricks is also a source: any model you design there can be exported as an STL, even if it only contains one piece. However, I have found that they are fairly low resolution, so they are fine for printing at life-size, but not so good if you're planning on scaling them up.

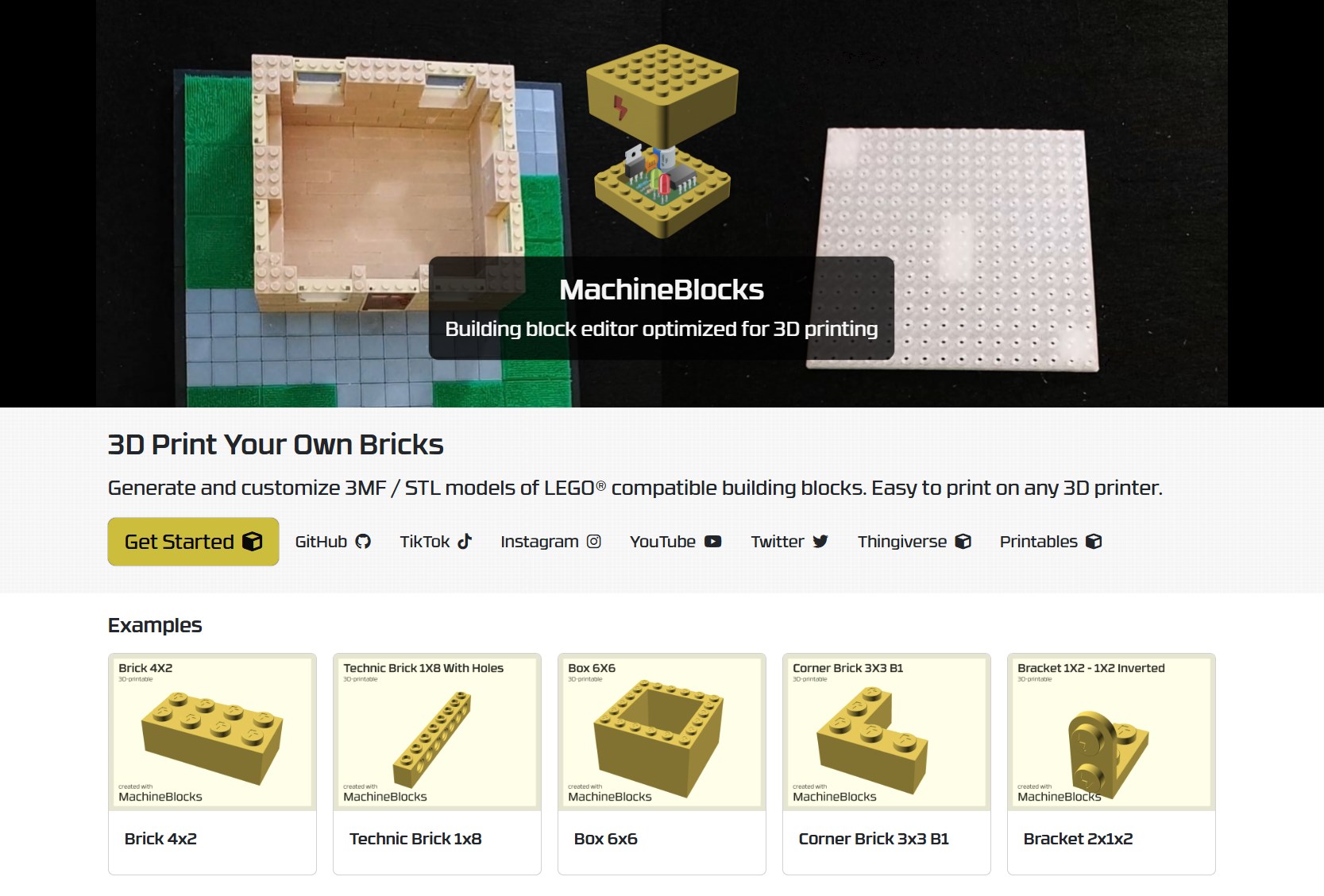

If you're feeling adventurous and want to create pieces that don't exist, like a 2x5 brick, you can use a website like MachineBlocks to generate a STL for virtually any compatible piece you can imagine.

If it's non-existent Technic pieces you're after, you might find them in my small collection on MakerWorld, created using OpenSCAD, a 3D modeller for programmers.

Printing 2x4 bricks

3D printers work a bit like a pen that uses molten plastic instead of ink. The most common type of plastic used is PLA, which is derived from renewable resources and is biodegradable.

To continue the pen analogy, layers of plastic 'ink', typically 0.2mm high, are deposited on top of each other with a 'pen' that typically has a 0.4mm diameter 'nib' (nozzle). After a layer is printed, the pen moves up 0.2mm and the next layer is printed on top if it, and so on.

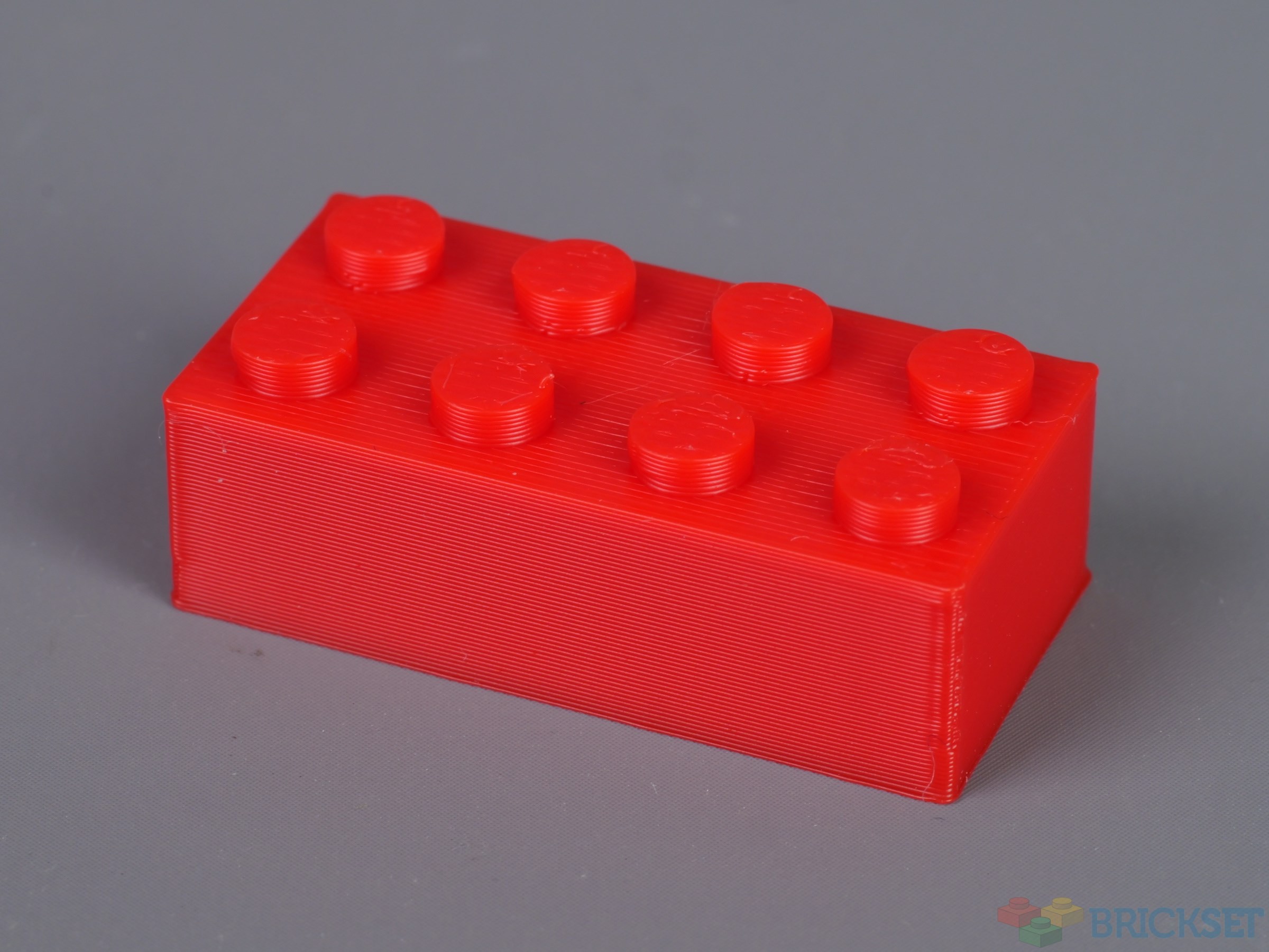

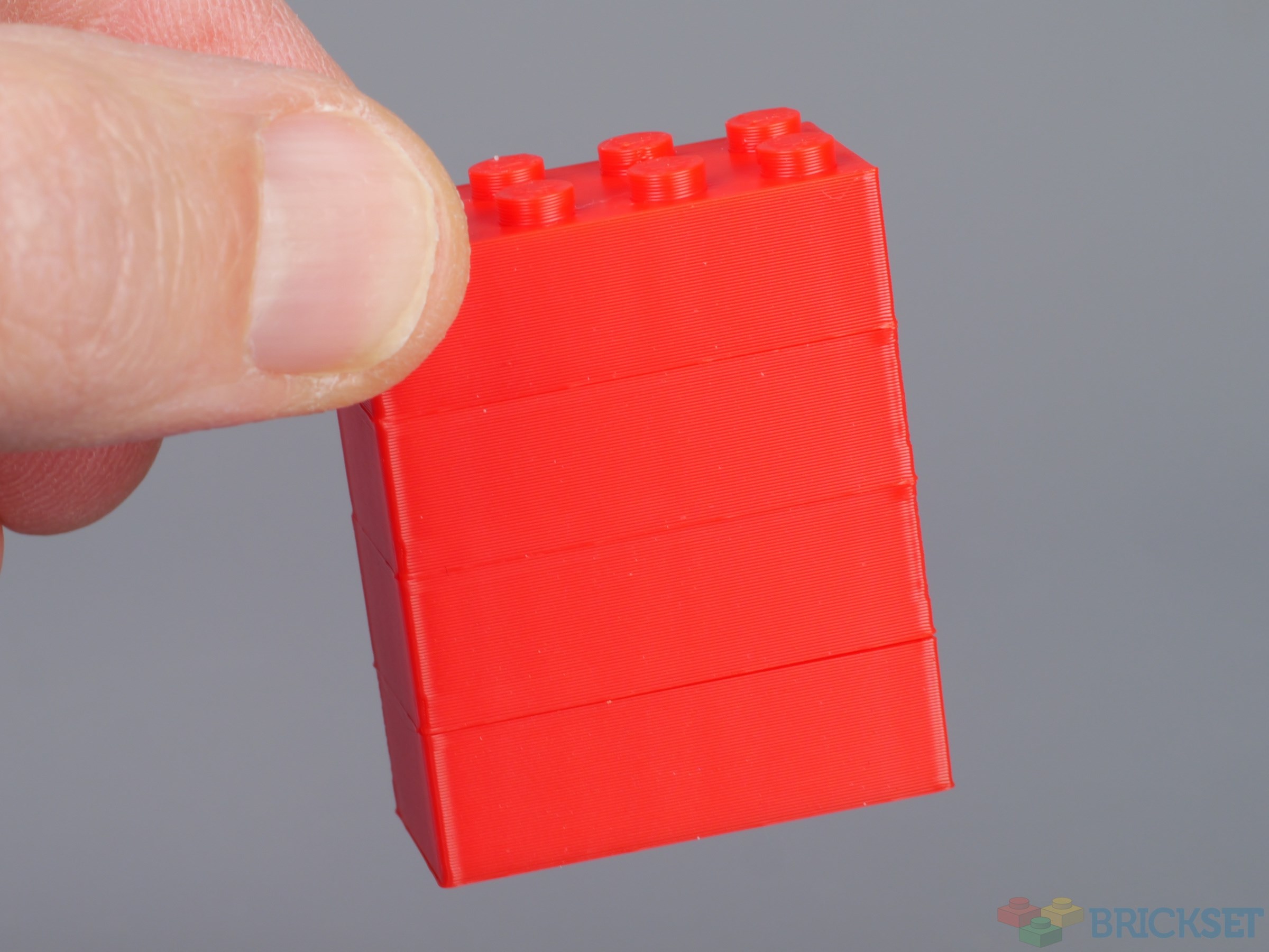

If you're printing small pieces and you want the best quality possible, you can use a 0.2mm nozzle and a 0.1mm layer height, which increases print time four-fold.

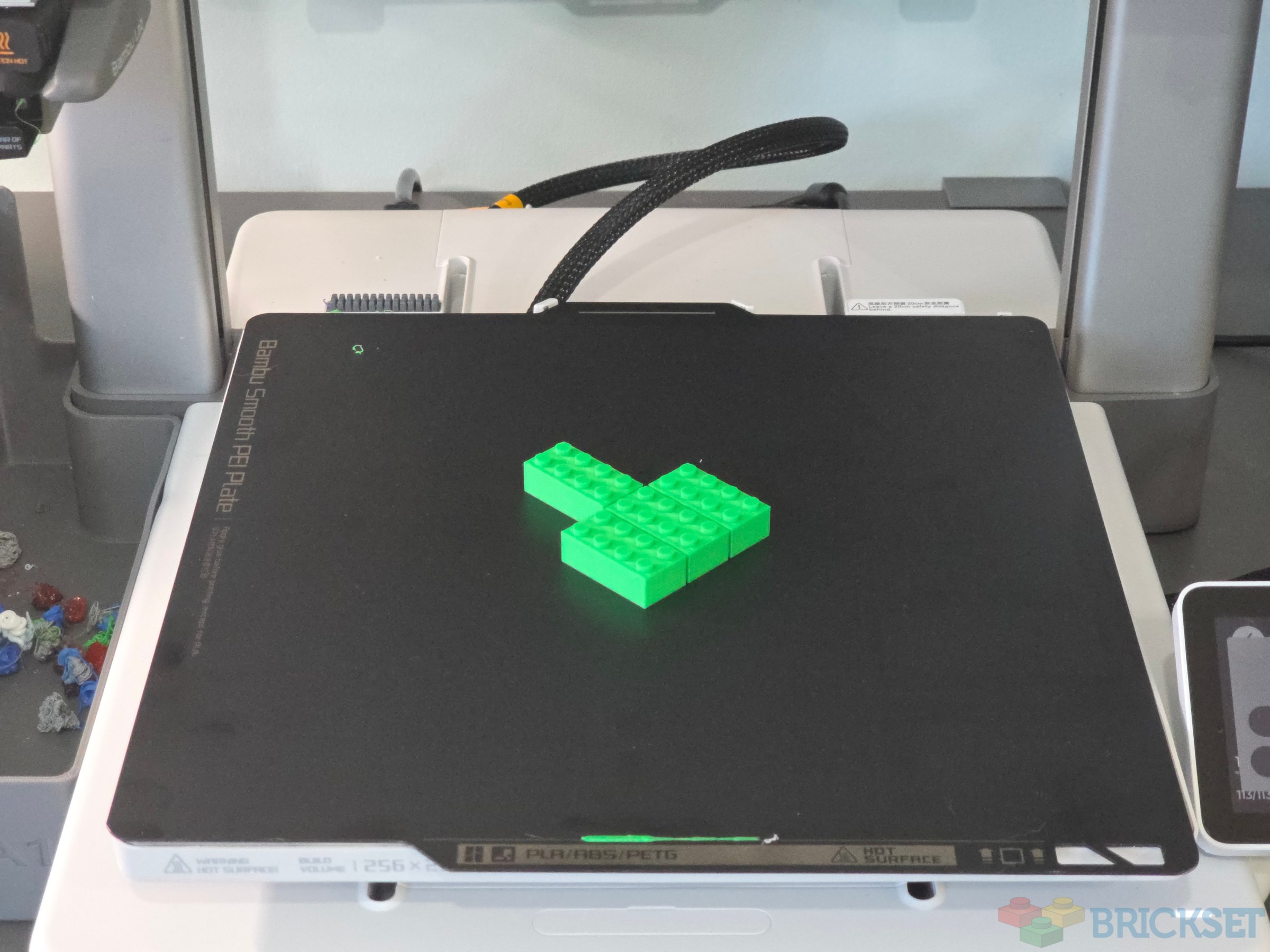

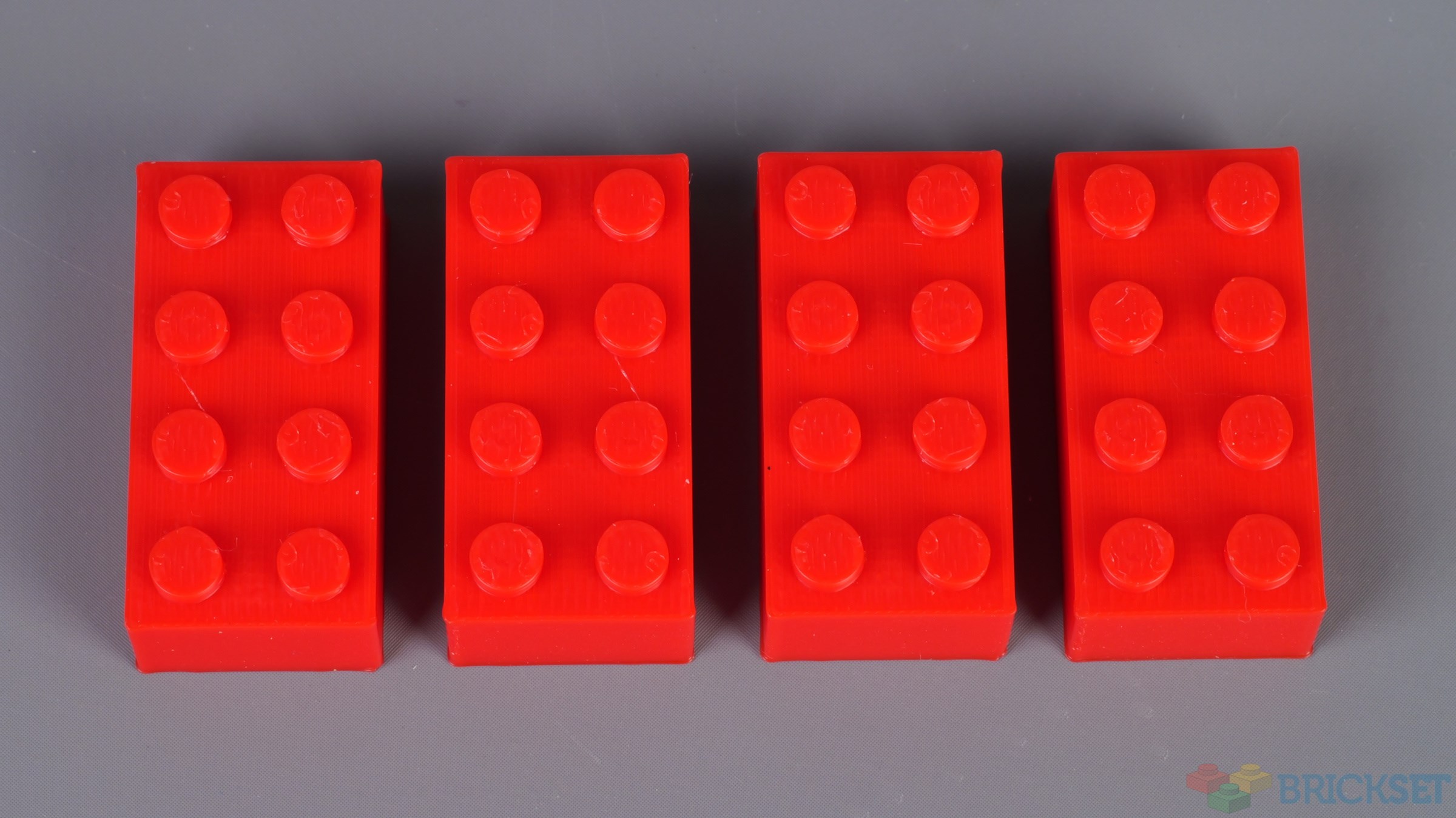

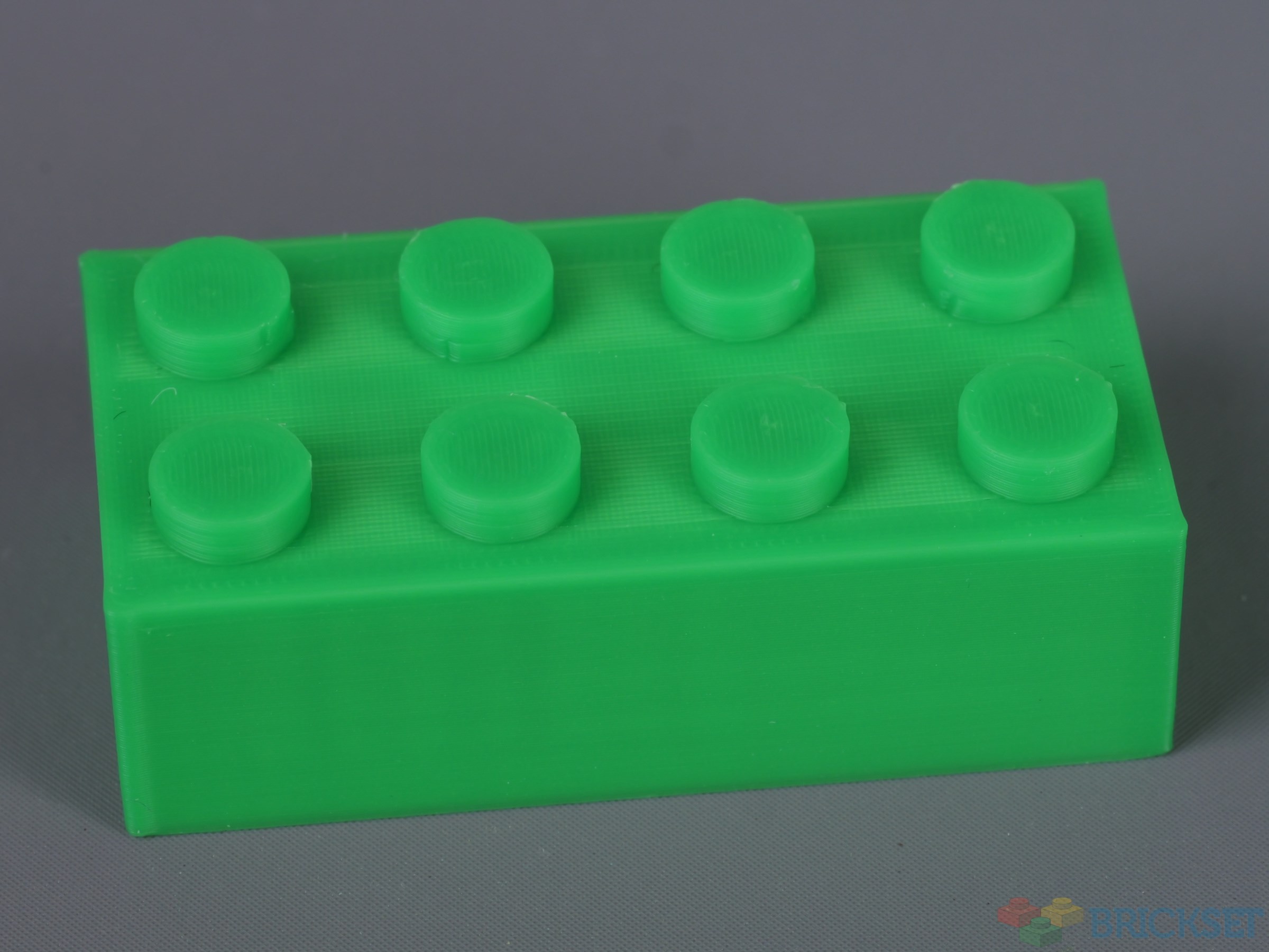

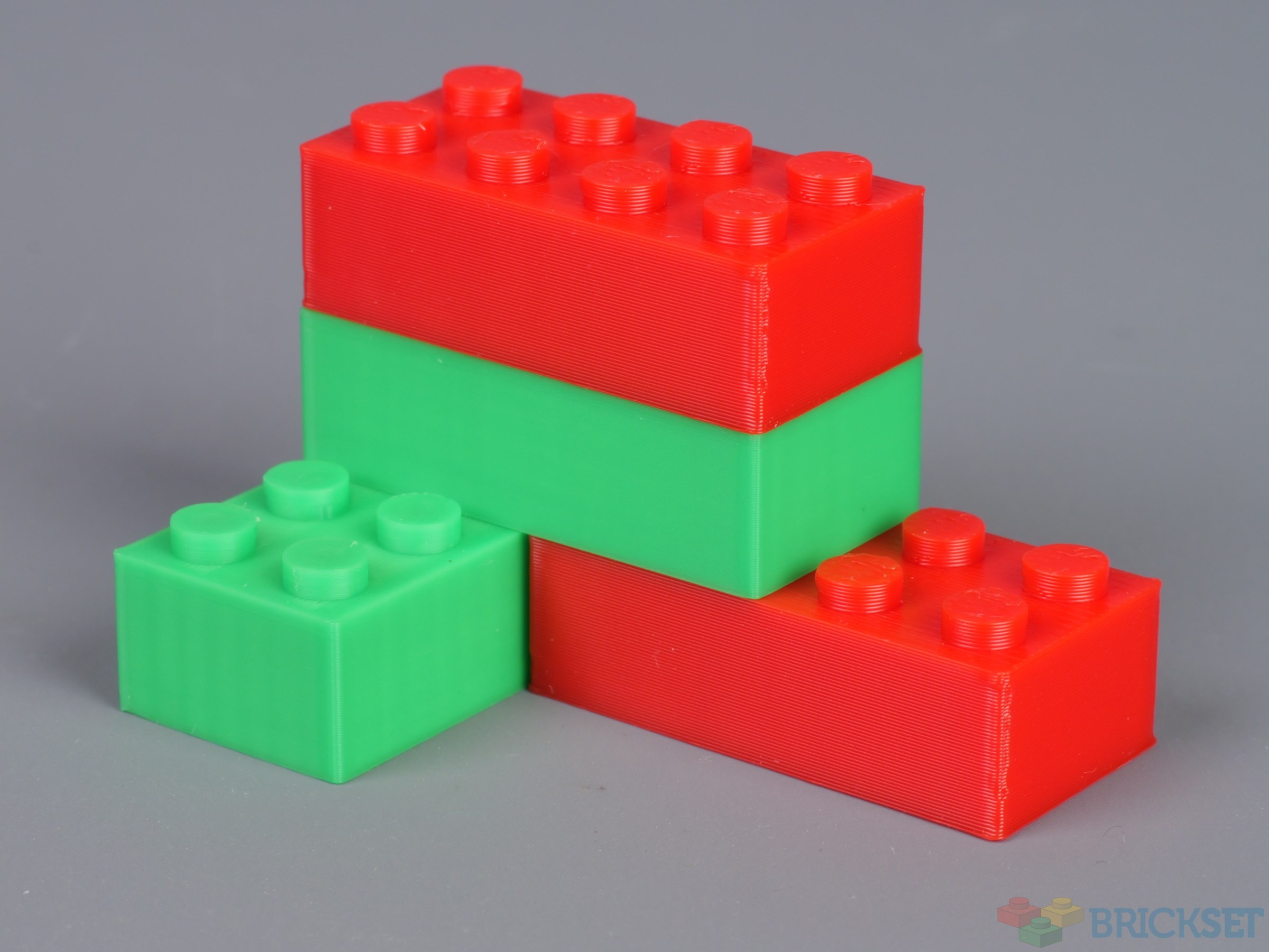

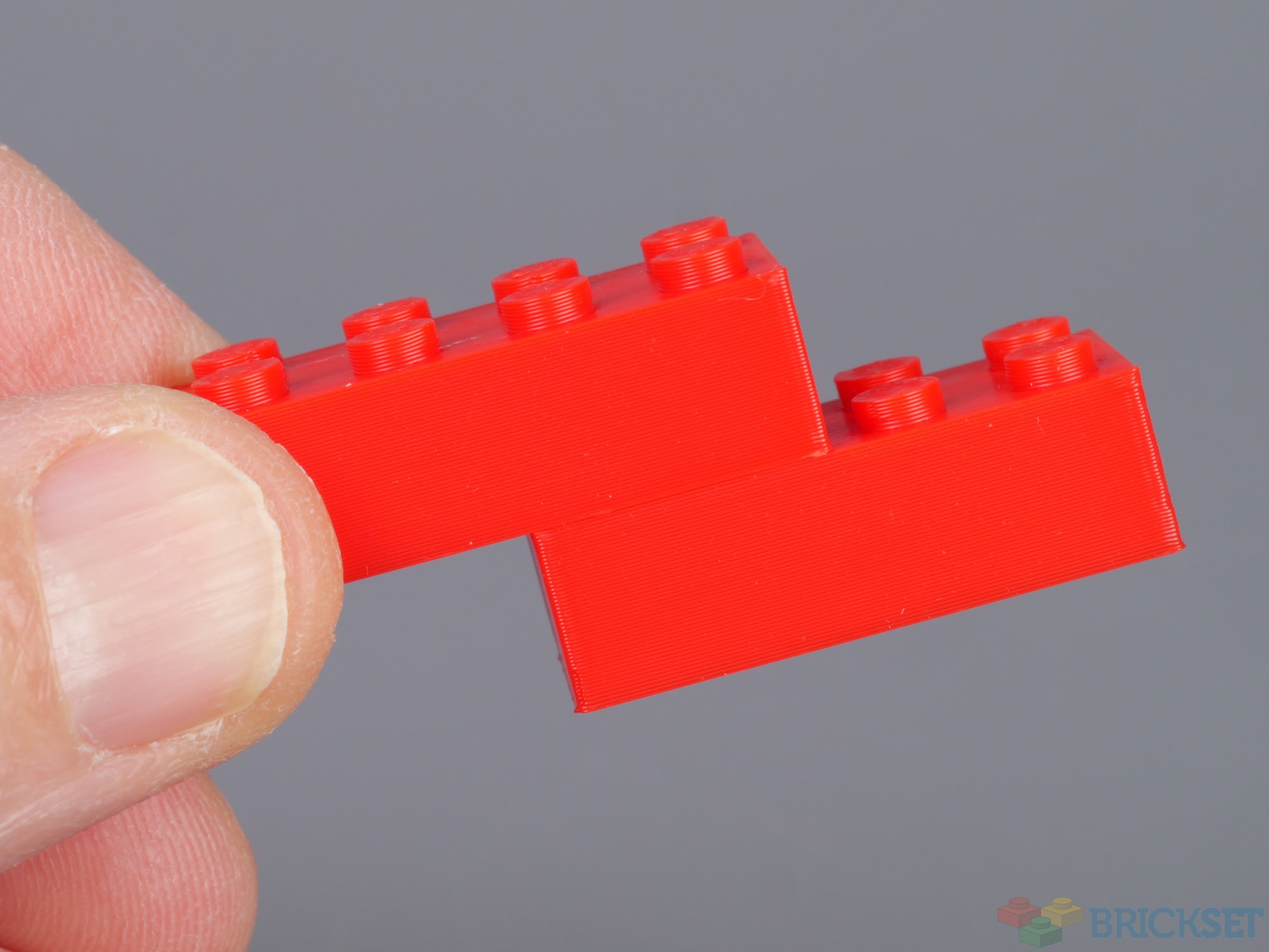

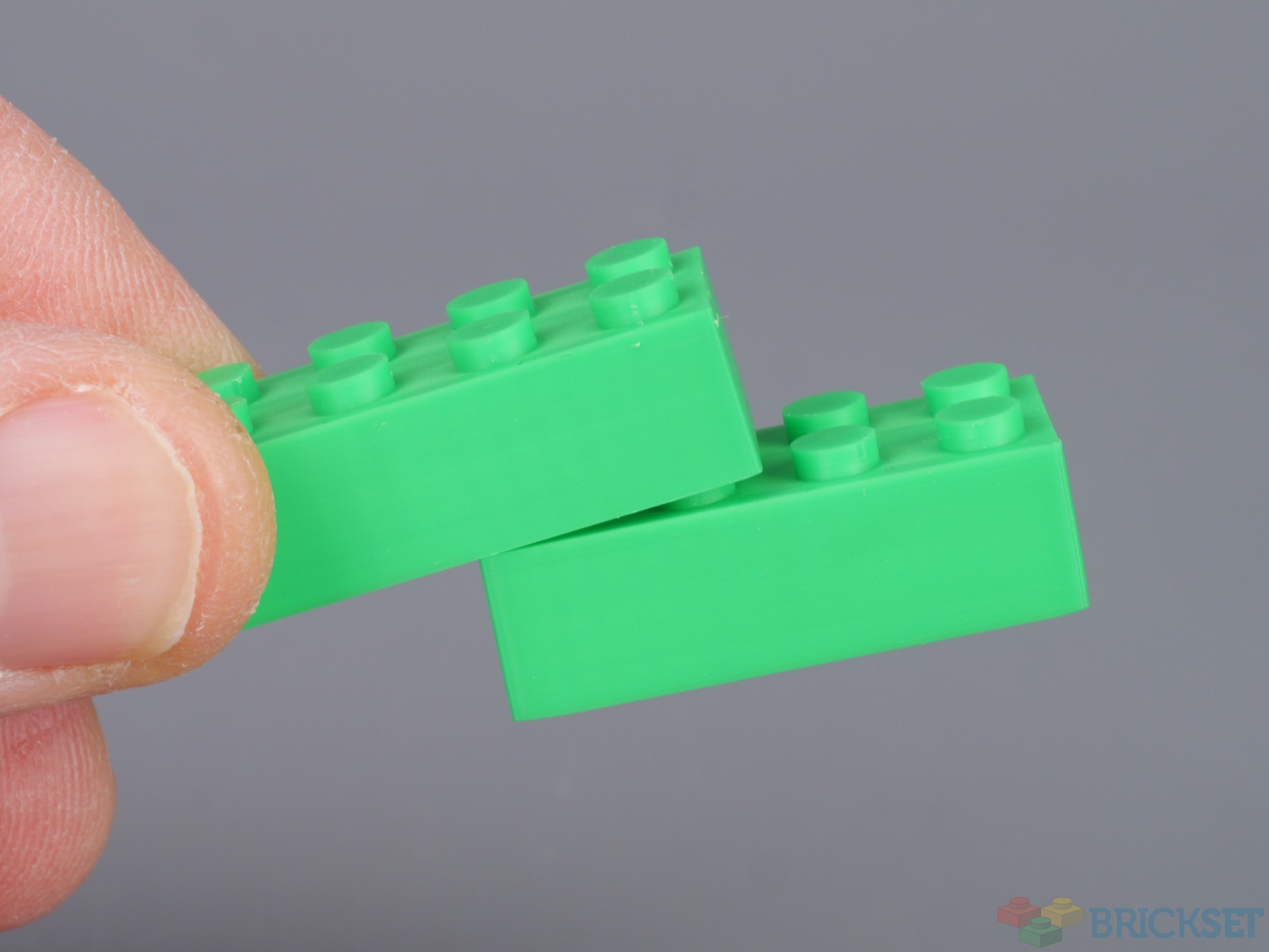

For this experiment, I used high-precision STEP files for the bricks that were created by Jonathan Twynham. I printed four green 2x4 bricks using a 0.2mm nozzle at a 0.1mm layer height, and four red ones using the more typical settings of 0.4mm nozzle and 0.2mm layers.

The four green bricks took two hours to print, the four red ones, 36 minutes.

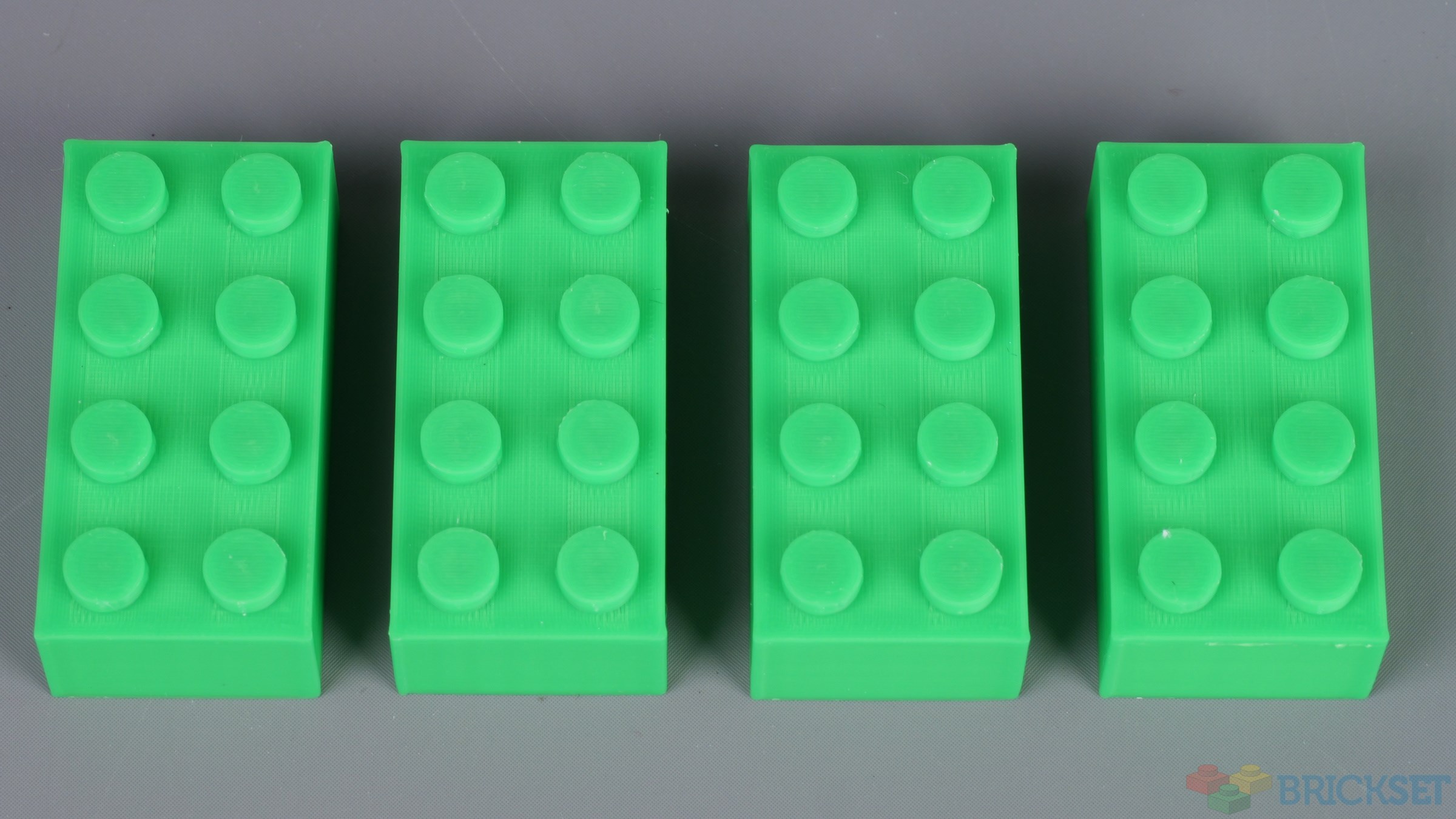

The quality of the green ones is just about as good as you're going to get out of a consumer printer. The 0.1mm layer lines are barely visible and the studs perfectly formed.

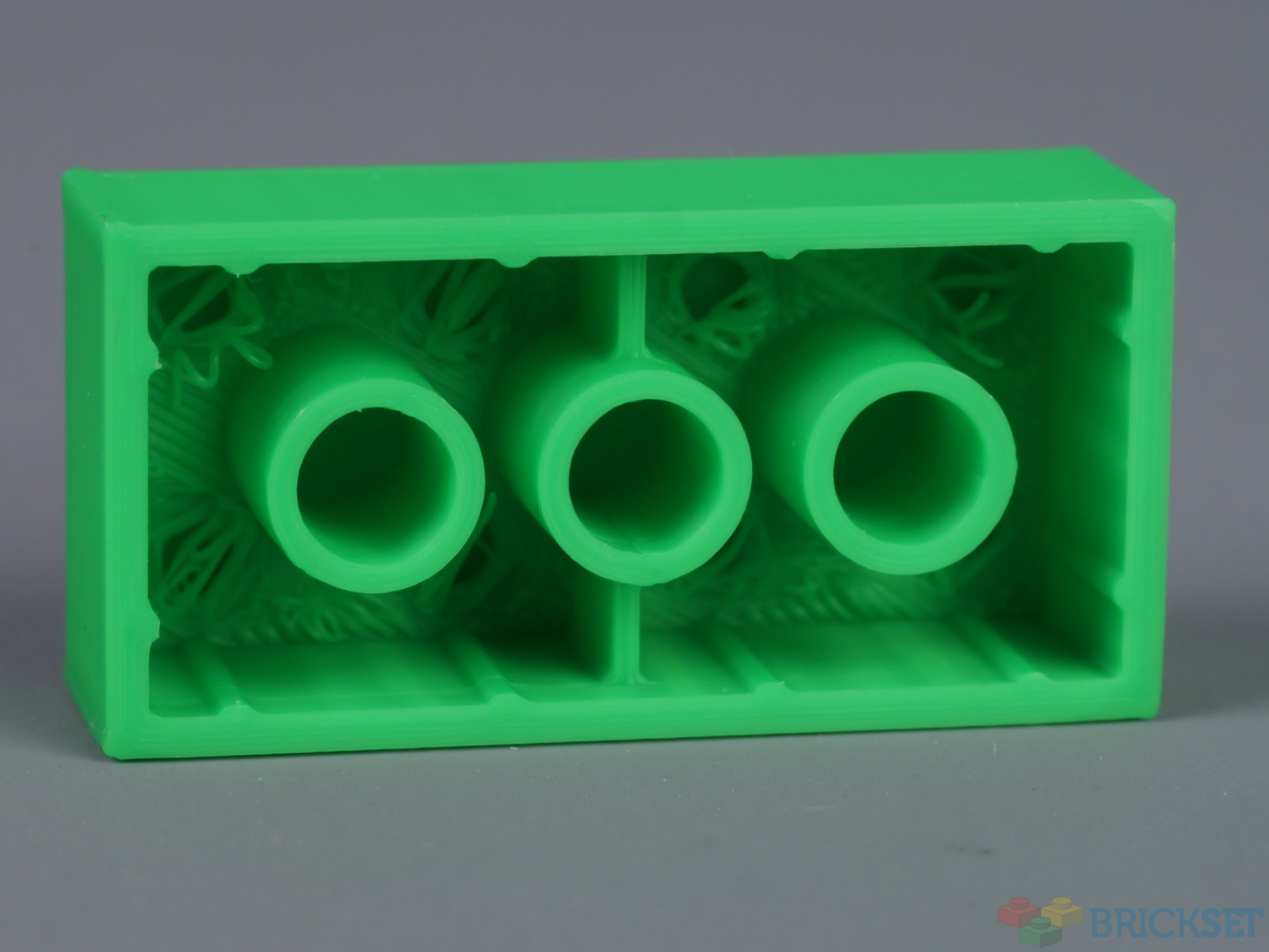

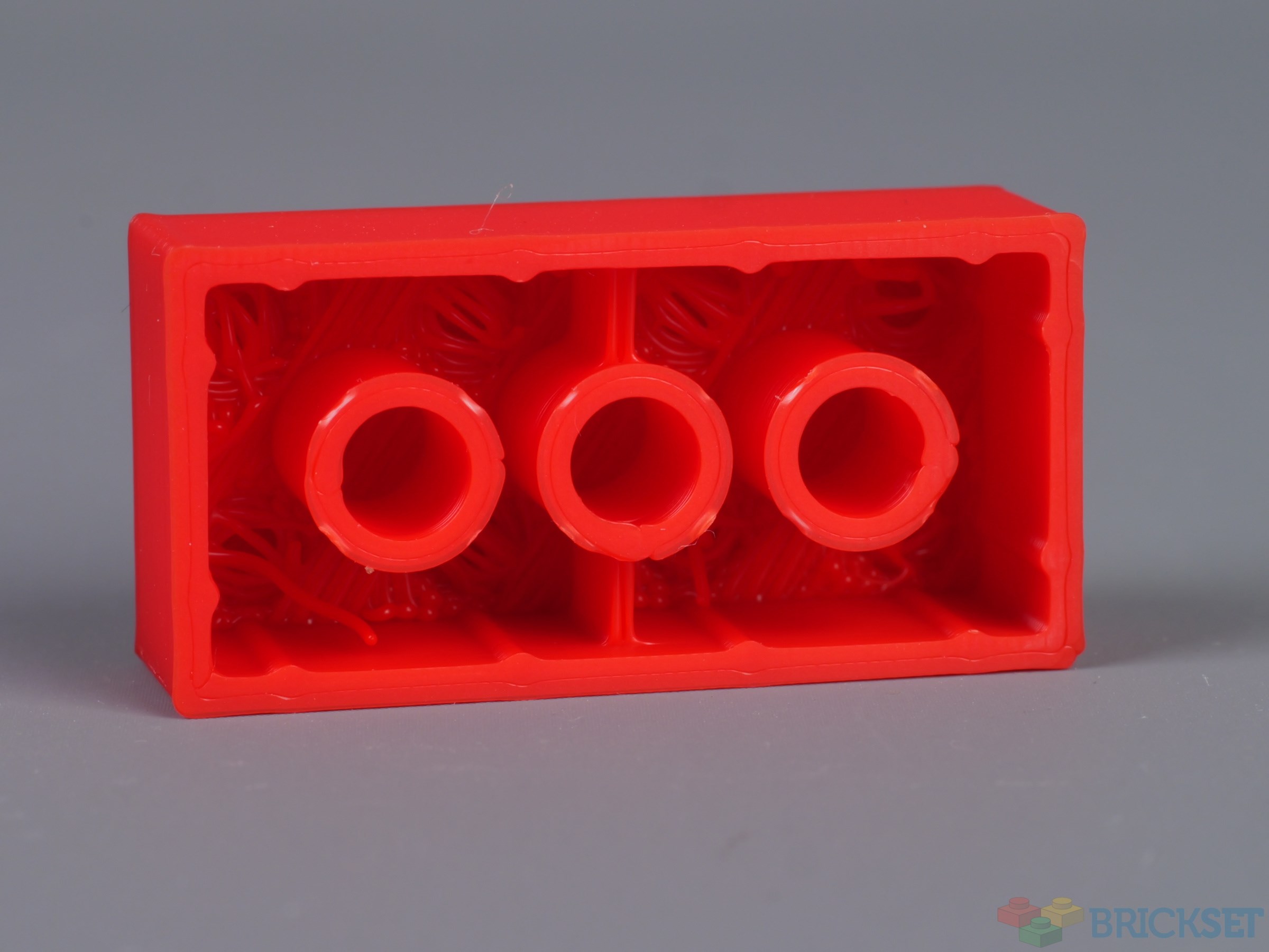

3D printers can't print on air, of course, so typically some sort of support structure is needed if the model you're printing has unsupported horizontal surfaces, like the bottom of a 2x4 brick does. Supports add time to the print and can be difficult to remove cleanly, especially on small items like this. It's possible to use a special support interface material to minimise this, but doing so increases print time and generates purge waste when the printer changes material.

I did not use supports for these prints, and you can see the result below. It doesn't matter when printing bricks, because the straggly stands of filament will not get in the way of the studs of pieces connected below it, but it would if it was a plate or tile.

The layer lines are more visible on the bricks printed with the 0.4mm nozzle at a 0.2mm layer height, as you'd expect.

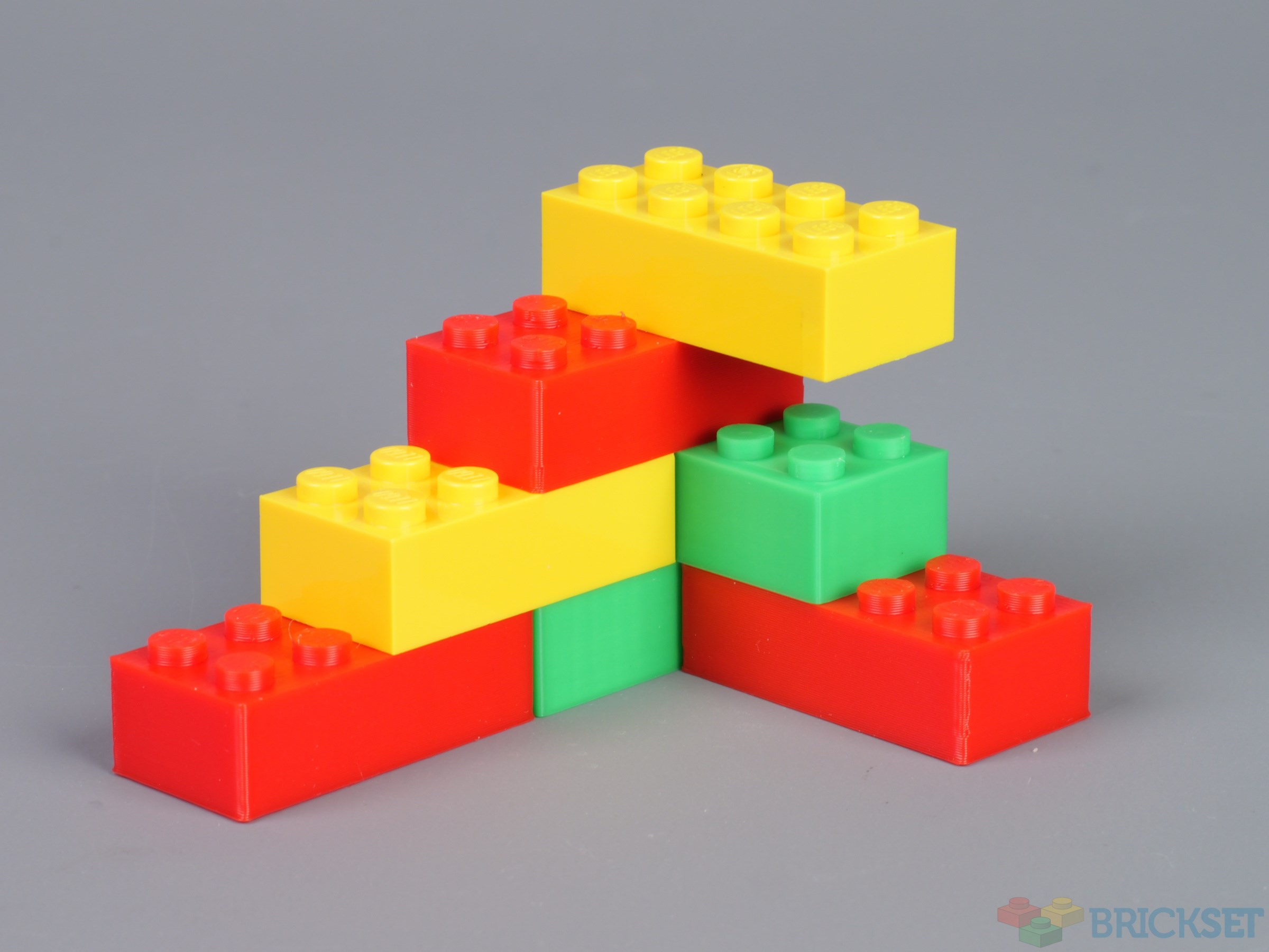

Both are perfectly functional, connecting to each other, and the genuine yellow bricks.

The all-important property of bricks -- clutch power -- is nowhere near as good as that of real bricks, though and, for some reason, it was slightly better on the red bricks than the green, which have hardly any at all. It's possible to tweak the model file to improve it, of course, but it would involve a lot of trial and error.

I hope this article has shown that it's certainly possible to print functioning bricks but, frankly, it is not worth the time and effort. There are times when you might want to, such as to create non-existent parts to meet specific building requirements, but generally it's just quicker, easier and cheaper to buy the real thing.

Things get more fun and interesting when you scale them up and create giant models, like those made by Matt Denton, though!

Real LEGO banana for scale.

84 likes

37 comments on this article

Interesting. Would it be possible to print the 2x4 bricks upside down, so the supports were on the struts and hence more accessible when cleaning up?

I appreciate the LEGO banana for scale

I’m not sure I can personally see much aesthetic difference between the lower and higher quality printed 2x4 bricks? Maybe the brighter green just shows up the lines more

There's a huge community of BIONICLE fans who are 3D printing their own elements - both existing pieces that are now hard to come by, or entirely new parts like Kanohi masks, weapons and armour. It's a really interesting part in this discussion that, if you were ever considering doing a follow-up to this article, could be fun to include.

Friend of mine uses his 3D printer for making models for the 'large metal cudgel' model battle system. He thought he'd try and make me a custom 'not-lego' model for christmas, and I can attest that his brick printing attempts, while better than the results here, still had all of the problems listed making it just not worth it unless you're doing it for novelty upscaled parts.

Remember, between brittle 3-D printed bricks and unavailable LEGO pieces there are alternate brands. Yes, I'm a heretic who LOVES to watch the world burn.

I feel as though I would be inviting my own versions of "brittle brown" without knowing anything else but this as an idea.

@Wavelength said:

"Interesting. Would it be possible to print the 2x4 bricks upside down, so the supports were on the struts and hence more accessible when cleaning up?"

Yes it is, and that would be a bit quicker, too. 3.5 hours at 0.2mm/0.1 layer, supports and a support interface material.

Looks like the red material has a lot of first layer elephant foot. (The first layer has to be squashed into the print bed to make it stick. That also often makes that first layer wider than intended, the slicing software normally has settings to compensate for this.) Ironically that may also be why the red has better clutch power.

Great article, very interesting topic. I was printing just about usable bricks 20+ years ago on a very early Lulzbot AO-101.

Would be interested of how easy it is to print images on existing Lego bricks. Basically to replace stickers.

Very interesting. I'm not remotely surprised that they don't have the clutch power, but then for me the appeal was always creating non-existant parts. Have you tried printing any gears or other moving parts and if so - how do they compare strength-wise?

I can't believe I see a bana for scale here!

@danishbricklayer said:

"Very interesting. I'm not remotely surprised that they don't have the clutch power, but then for me the appeal was always creating non-existant parts. Have you tried printing any gears or other moving parts and if so - how do they compare strength-wise?"

Ys, but I've not put them to use yet.

The most interesting use for me would be printing Monorail track pieces, both of the existing designs as well as new types.

Like you said, printing existing and common pieces yourself just isn't worth the effort.

@AustinPowers said:

"The most interesting use for me would be printing Monorail track pieces, both of the existing designs as well as new types.

Like you said, printing existing and common pieces yourself just isn't worth the effort. "

There look to be some good designs available: https://www.printables.com/search/models?q=monorail+track

Or you know. You could print them rotated, then you don't need any supports and everything will print nicely.

The upscaled bricks look so huge compared to the banana!

And the printed microbanana in the previous article had black spots. It is because the material is biodegradable?

You're going to LEGO jail. And not even one of your own making.

@Dannygast said:

"Or you know. You could print them rotated, then you don't need any supports and everything will print nicely."

I'm struggling to think which angle would prevent the need for supports and not be printing on air given the intricate nature of the underside and the studs. What would you suggest?

I believe you can also export 3d files from stud.io. The time I did it I believe it made the brick too large though.

And thus is displayed the important difference between the phrases 'Can you?' and 'Should you?'.

Lego banana for scale...LOL!

@MegaBlocks said:

"Would be interested of how easy it is to print images on existing Lego bricks. Basically to replace stickers."

It can be done with a UV printer. I saw a YouTube video where a guy printed a poster on a 2x3 tile, then shrunk the design down and printed it on a minfig torso. It looked pretty good. No idea how much the printers cost, though.

@Huw said:

" @AustinPowers said:

"The most interesting use for me would be printing Monorail track pieces, both of the existing designs as well as new types.

Like you said, printing existing and common pieces yourself just isn't worth the effort. "

There look to be some good designs available: https://www.printables.com/search/models?q=monorail+track"

That's exactly what I meant.

@Jack_Rizzo said:

"There's a huge community of BIONICLE fans who are 3D printing their own elements - both existing pieces that are now hard to come by, or entirely new parts like Kanohi masks, weapons and armour. It's a really interesting part in this discussion that, if you were ever considering doing a follow-up to this article, could be fun to include."

Yeah. Bionicle customs, monorail parts, custom train track, accessories. Basically where 3D printing is at now won't replace a genuine LEGO part, but it can be used to fill the gaps LEGO missed in their often retired or rarely used lines.

@huw I forgot to ask in the "color-matching" article, but finding a good Pearl Gold like color would be a perfect way to assemble sets such as the Mandalay Bay Las Vegas that has some exclusive Pearl Gold elements...

@StudMuffin24 said:

" @huw I forgot to ask in the "color-matching" article, but finding a good Pearl Gold like color would be a perfect way to assemble sets such as the Mandalay Bay Las Vegas that has some exclusive Pearl Gold elements..."

Indeed. As well as colour one would want to match the 'shine' as well, and I think a silk filament would be too shiny.

@xboxtravis7992 said:

"Yeah. Bionicle customs, monorail parts, custom train track, accessories. Basically where 3D printing is at now won't replace a genuine LEGO part, but it can be used to fill the gaps LEGO missed in their often retired or rarely used lines. "

It is indeed amazing to create custom Bionicle parts, I do it daily and I find it amusing how the technology seems to be made almost specifically for this niche hobby.

When printing with a 0.2mm nozzle at layer heights of 0.06mm I am able to create parts where the layer lines are almost invisible. The complex geometry of Bionicle parts lends it self to hiding the flaws of 3D printing, and when using it for masks and armor add-ons the support locations can be strategically placed so their scarring on the parts is hidden. Because armor and masks are added on to skeletons made from existing Lego parts, the durability is not an issue and only the axle or pin hole connection point needs to be tweaked for correct clutch power.

All in all, even with FDM-based printing I am able to print parts that almost look injection-molded once placed on a Bionicle figure, though the silk filaments provide some durability issues on mask axles.

@AustinPowers said:

" @Huw said:

" @AustinPowers said:

"The most interesting use for me would be printing Monorail track pieces, both of the existing designs as well as new types.

Like you said, printing existing and common pieces yourself just isn't worth the effort. "

There look to be some good designs available: https://www.printables.com/search/models?q=monorail+track"

That's exactly what I meant. "

I had a friend with a 3D printer print me a dozen of those straights and some half-curves last year, to supplement my existing track.

The clutch power is terrible compared to genuine monorail track, but it's 'good enough' and certainly beats the current bricklink prices!

I've had no problem using them at a couple of shows last summer. Trains ran just as well on the printed track as on the genuine ones.

I guess resin printing would be the perfect printing method to achieve good surface quality for that size of print.

Finding a resin that is dimensionally stable enough, not brittle and that does not cost a kidney is another problem though.

Thank you for link to printables, I've always wanted the 7996 Double Crossover Track shown here as over £100 in secondary market too much.

Am I the only one who thinks of 3D printers as "Replicator 1.0?"

I have an SLA 3D Printer and used it to create custom parts for minifigures. For clutch power I just did the trial and error testing as changing the basic geometry used on the inside of bricks in Blender is as easy as editing a text document when you just sit down to learn it for a few weeks. One could just quickly make edits of the file of a brick for different clutch strengths and print those parts simultaneously, even easier when you already have a failed print and know the direction in which you must go, more or less clutch. Once you have these findings of the best dimensions for good clutch you could then easily apply these dimensions to every other part. Editing is extremely fast and easy once you know what you are doing.

I would not recommend printing the unchanged Mecabricks files as they are rough because some of them are taken from older LEGO video games which use shaders to smooth out some areas of the parts.

Having done the cost calculation for the Resin 3D Printer with the help of a website it makes perfect sense to print out parts when you use the full size of the print bed and do the more complex pieces, not ones that are 10 or 20 cents per copy. 80 parts the size of a minifigure helmet would take 4 hours to print and cost about 10 cents in material and write-off cost for the SLA 3D printer as the most expensive estimate. With a printbed of about 15x20cm you can print 80 pieces simultaneously at 4 hours of time since the entire printlayer of every object is created simultaneously unlike with the FDM printers. There is a noticeable post-processing time, especially when you are going to add a print or have to paint the base plastic in a different color which could be done by using a spray gun with an acrylic paint once you have found the perfect shade or mix of multiple colors for a shade. Disregarding the time and effort it takes to set this up which for me was about half my leisure time over the course of 6 months I would say the largest factors to the cost per part ultimately is how much you want to realize your own unique part ideas, and if what you want to make is a part with an equivalent made by LEGO or sold on Bricklink, how expensive the closest equivalent from Bricklink or LEGO is, and finally, how much you value your time. I am looking at somewhere between 40 or 60 cents of cost per otherwise non-existent helmet piece depending on how I would theoretically pay myself a wage to do that as a job, ignoring the material costs of painting and the mostly optional printing. Looking at the hair and helmet pieces available from LEGO this price is only beat by the most common or least in demand headwear pieces.

@Huw said:

" @Dannygast said:

"Or you know. You could print them rotated, then you don't need any supports and everything will print nicely."

I'm struggling to think which angle would prevent the need for supports and not be printing on air given the intricate nature of the underside and the studs. What would you suggest?"

In Resin printing you would need to have to rotate the piece so the first layer would be the tiny tip of one of the bricks edges. As if you want to poke the printbed with one of the bricks corners. Supports go along the very edge of the brick and some parts of the side facing the printbed.

@AustinPowers said:

"The most interesting use for me would be printing Monorail track pieces, both of the existing designs as well as new types.

Like you said, printing existing and common pieces yourself just isn't worth the effort. "

This is all I want. Straight monorail tracks are way expensive.

@Anonym, thank you for your interesting input.

So, question, @Huw, does this mean if LEGO ever released the file for the duck, train, pogo stick, people would be able to print them? I've been fascinated by the duck, but living in the US, I can't get one, without paying a lot...

@Huw said:

" @AustinPowers said:

"The most interesting use for me would be printing Monorail track pieces, both of the existing designs as well as new types.

Like you said, printing existing and common pieces yourself just isn't worth the effort. "

There look to be some good designs available: https://www.printables.com/search/models?q=monorail+track"

Great. Now I desperately want one of these Matt Denton upscaled LEGO builds.

@Modeltrainman said:

"So, question, @Huw, does this mean if LEGO ever released the file for the duck, train, pogo stick, people would be able to print them? I've been fascinated by the duck, but living in the US, I can't get one, without paying a lot..."

That’s an entirely different format of 3D printing, which is more durable than filament prints. In that format, you’re laying down layers of powder and fusing some of the powder together to produce the piece, so the unfused powder supports everything without needing to add removable structures. You absolutely could make those parts with the correct file, but if you’re doing it with filament, it’s going to look like garbage and won’t last much longer either.