Review: 42082 Rough Terrain Crane

Posted by FlagsNZ,

There will be debates amongst Technic enthusiasts about which set represents 2018's Flagship of the Technic theme. Is it the 42083 Bugatti Chiron or will it be the 42082 Rough Terrain Crane?

At 4057 parts, 42082 Rough Terrain Crane sits as the Technic set with the most number of parts.

Cranes have featured in the Technic range from 1978 when 855 Mobile Crane was released in the second wave of Technical sets.

Read on as I review the first half of building this latest Technic mobile crane model. Part 2 will be posted tomorrow.

The box

As would be expected for a Technic set that breaks the record for the most number of parts, the box is huge.

The front of the box has the crane working in the rough terrain of a building site and there are sections of a prefabricated building being assembled.

The dimensions of the completed set are shown on the right-hand side and indicate that the boom, when fully extended, reaches 100 cm (39.4 inches).

This set includes Power Functions.

The rear of the box shows the play features of the set as well as some images of the B-model, a Pile Driver. The B -model uses the same chassis as the main model.

The box flap opens to show another image of the Rough Terrain Crane. Again, you get a sense of the extreme size of the completed model.

Instructions and sticker sheet

The instructions have been split into two bound books and come in a plastic bag that also protects the sticker sheet.

There is a large sticker sheet.

The build - Book 1

The parts are arranged in numbered bags for the 13 principal building steps. Four tyres, four red rims, and the Power Functions battery box and L Motor are loose in the box.

There are eight bags, for building steps 1 to 4, in a smaller, plain white box. A further five loose bags, numbered from 5 to 8, are needed for the building steps of Book 1.

Build Step 1

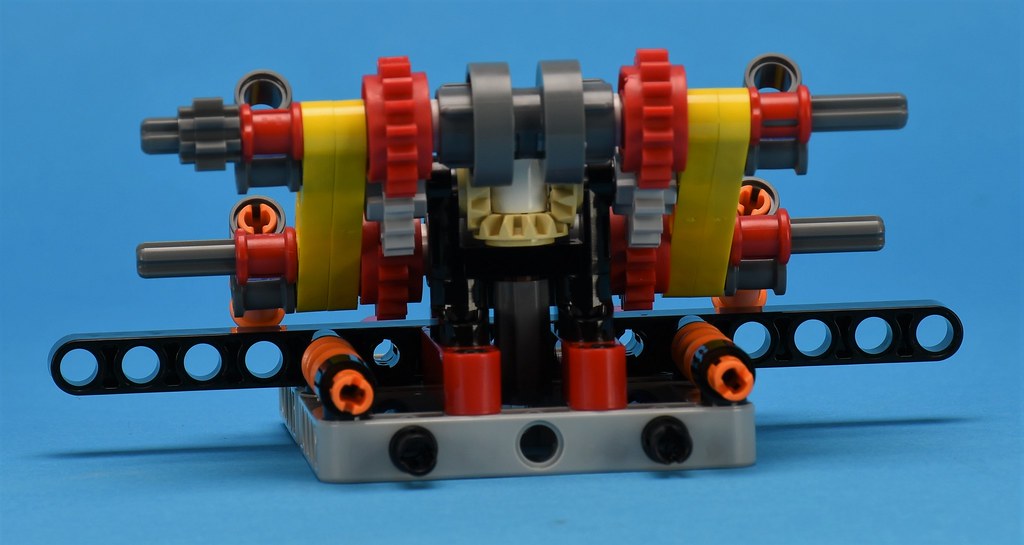

Building step 1 assembles the two gearboxes of the chassis. From the earliest stages it is difficult to see how this will all fit together.

The drive input to the chassis comes through this series of bevelled gears. In this view, the subassembly is upside down.

Build Step 2

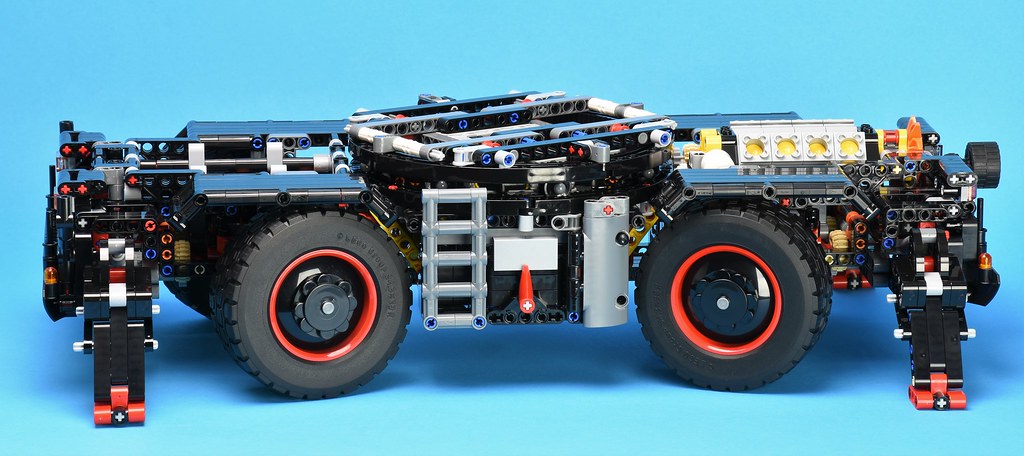

By the time that building step 2 is completed the basic form of the chassis is taking shape.

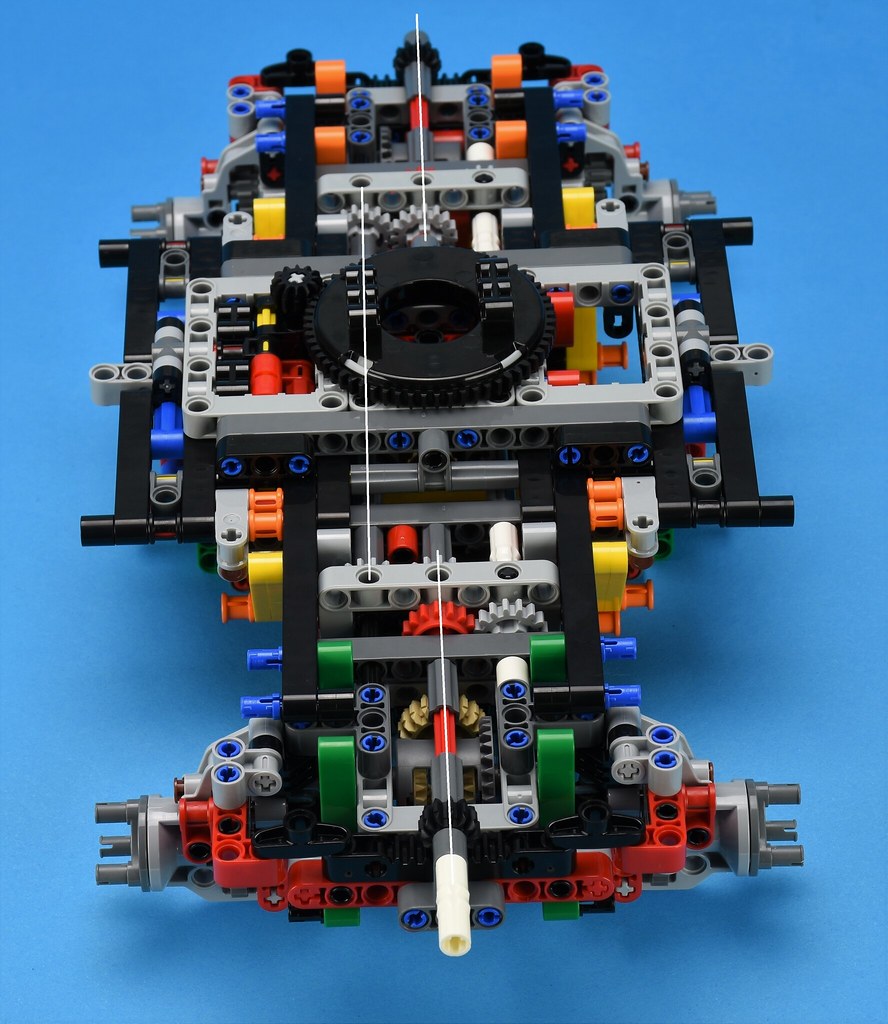

The Rough Terrain Crane employs four-wheel steering and so both axles have a rack and pinion steering system. It is important that at building step 205 (page 103) the wheel hubs are aligned straight and that the two steering cross axles are upright (like an upright cross) when the green coloured-coded axle is married with the main assembly.

This alignment is correctly indicated at building step 268 (page 128) when the orange colour-coded axle is married to the chassis but if the green axle was not aligned correctly earlier in the build then the two driving axels will not be aligned with each other.

The thin white line in the image below shows how the steering system bypasses the main slewing turntable.

Build Step 3

Build step 3 assembles the outriggers. In order to have all four outriggers synchronised, all four small linear actuators need to be extended by the same amount as the outriggers are assembled. There are 1:1 scale pictures in the instructions as the linear actuators appear in the building steps.

If the linear actuators differ in length slightly when assembled then they will auto-adjust themselves to the same length using the built in clutch inside the actuator itself when the outriggers are first extended or retracted.

Build Step 4

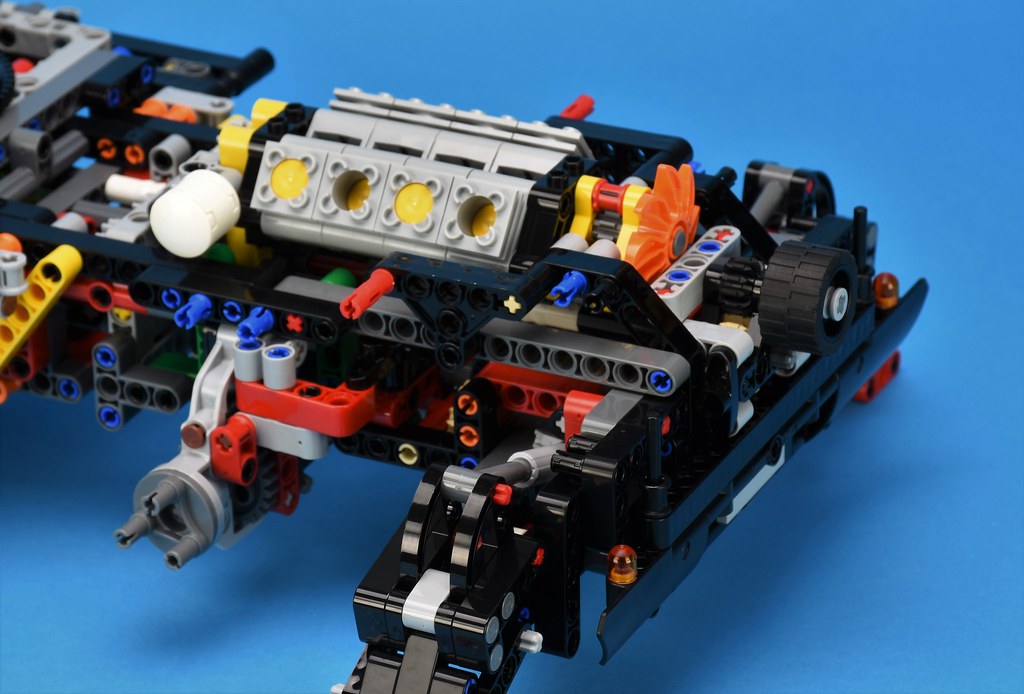

Build step 4 assembles the rear bumper and the V8 engine and completes the parts found in the plain white box.

The orange cooling fan (saw blade) has not been seen in many sets in this colour.

For build steps 5 to 8, there are five numbered bags that were loose in the big box.

Build Step 5

Build step 5 assembles the front bumper and the crane's slew ring.

The slew ring is made using 11x11 circle gear racks in black for the first time. This is the only new part, in a new colour, in this set. There are eight black 11x11 circle gear racks.

There is an ingenious roller bearing race incorporated into the slew ring.

The slew ring fully assembled.

Build Step 7

Build steps 7 assembles the two lockers and access ladders under the turntable as well as adding the gear selectors for the chassis' two Power Functions options: turntable and outriggers.

The left locker will eventually house the tool box.

The right locker is open and will eventually house some lifting chains.

Build Step 8

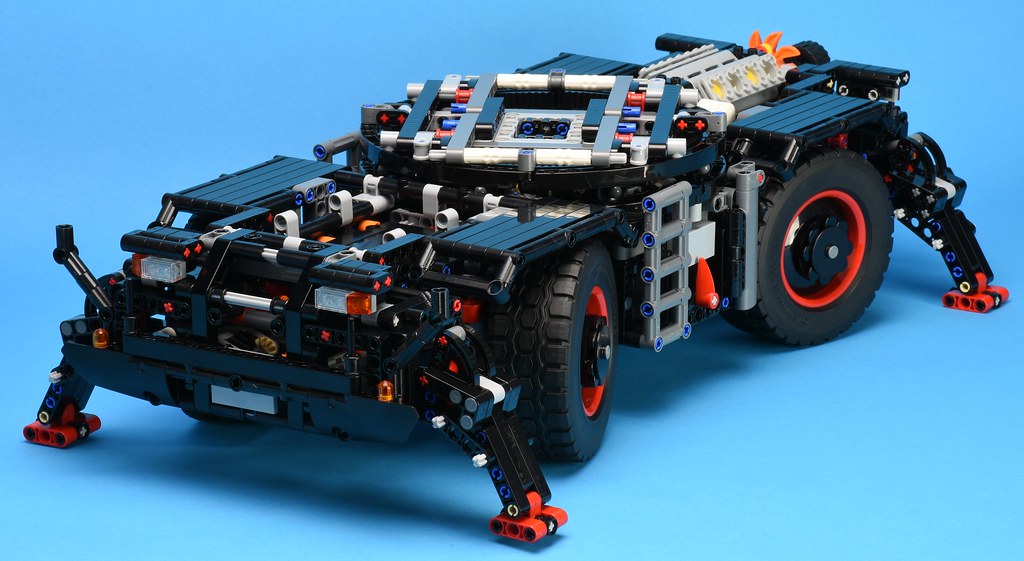

The final build step for Book 1 is step 8. This sees the four mudguards and wheels added to the chassis.

The four wheels have been added which have a clever use of round 1x1 black tiles to represent the nuts holding the rims onto hubs.

At this stage, the four outriggers are not touching the ground when fully extended.

Overall opinion - so far

One thing I noticed while building this model was that having the parts separated into numbered bags made the building process so-much easier. I normally need a large dining-room table to sort and spread out all the parts for these larger Technic sets.

For this build, I was able to just open the required bags and start building. I didn't need to sort any of the parts smaller groupings and this made the building process so much easier.

Using numbered bags is an easy way of ensuring that mistakes are spotted earlier as if any significant part remains, it must have been missed out during this building stage. There were some stages where there were no spare parts remaining on completion of that step.

The part that I noticed was used more than ever before was the Technic pin connector hub with 1 pin with Friction Ridges Lengthwise. There are 84 of these parts in this set and most of them appear in the first half of the build.

This part has been used extensively for multi- directional reinforcing. I can see variants of this part appearing in Technic set in the near future.

Part 2 - Book 2

Part 2 of the review of the 42082 Rough Terrain Crane can be seen here. It looks at assembling the crane superstructure and takes an overall look at the completed model.

66 likes

16 comments on this article

I am not a fan of real Technic sets. But as usual I am very impressed by the quality and complexity of the building process. I can't imagine to design something like this, it would be just too difficult for me to create. The level of gear boxes seems so high that I just can applause to the designers creativity. I am then not completely surprised that issues can happen in the instructions as mentioned in the review... I guess that one can easily make a mistake while building. I must also say that the final result is impressive too (according to the pictures available). Good pics and review, which help me to appreciate sets I would otherwise not even really look at on a shelf, or just a glance because of the huge box.

"In order to have all four outriggers synchronised, all four small linear actuators need to be extended by the same amount as the outriggers are assembled."

I don't think it matters what stage they are at when you assemble the model, all you have to do is power the linear actuators to their max length when the model is built and the clutch inside the actuator will kick in on the appropriate actuators until they are all the same length. They will kind of 'auto-adjust'.

Stop the building there, that is the most badass Batmobile already. :)

The irony for me is that there are now so many steps, presumably to make building easier, that it is now more likely you will miss a few, especially if one has other things on one's mind. If you get to the end of a massive Technic set and realize a mistake was made it can be very difficult to perform "surgery" to correct it. Sometimes performing surgery can be very rewarding, though!

Too bad this set isn't remotely controlled like the bulldozer, excavator, crawler, and Volvo truck. That would have really made this the mother of all cranes.

It looks like it’s going to be amazing once completed!

@Peanuts one of the offical images resembling blueprints of the vehicle actually has a minifig for comparison.

Thanks for the alignment tips - that'll save some heartache in future.

@ Julie Lamport:

I never considered that. Your point is well made and I have edited the text accordingly. The alignment of the steering comment still stands though. Thanks for the advice.

I've also fixed the hyperlinks in the introduction.

So I’m not the only one who though this was a Bat vehicle.

I feel like it would be awesome if LEGO decided to make a Star Wars UCS Minifig Scale Set using technic elements. Technic tends to add a huge complexity to the final product (much akin to greebling) and the size of this model works almost perfectly for a Sandcrawler or AT-AT. Just a thought.

This set is absolutely amazing, though. I love watching them come together. Good review!

@Nexus Riles the motorized AT-AT from 2007 was very Technic, with a system shell. Also, many of the UCS sets are Technic skeletons with system pieces on the outside for aesthetics.

so it has a lot of the most annoying technic connector. each time I see this part, I dread the 30s I'll need to succesfully push it into a pin hole.

I love the design of the set but the scenery in the background of the main picture in the set box looks a little polluted.

One thing I love about LEGO Technic, despite not having much personal interest in owning the sets, is the balance between collectability and play value. We must give props to LEGO for that, knowing it is extremely difficult to capture a value of such depth among sets with thousands of tiny pieces.

The fan isn't common in orange? That's the only color I have the peice in, and I have 3 of it. Nice review. I won't be getting it, but I'll read through the instructions to learn some tips and tricks.

I really am puzzled by LEGO's move to fancy-pants colours for the mechanisms. What are they trying? Lower the age for building these models? 6 year old kids can as well build this when all is in black and grey.

Or do they want to extend the age upward? Make these models suitable for 90+ granddaddy's?