42055 B model: Mobile aggregate grader

Posted by Huw,

It's rare for the alternative 'B' models of Technic sets to garner much attention as they are usually not that interesting. However, that's not the case with 42055 Bucket Wheel Excavator. Many of you have been asking about the mobile aggregate grader to find out whether it's worth building: does it work, how does it work, how many parts it uses and so on.

So I thought it was only right that I should build it myself to try and answer those questions. I didn't take my BWE apart, I bought another set, from Amazon.co.uk at a bit below RRP.

This isn't a review as such, but my observations on building and operating it.

TL;DR: yes, it works, but not without problems.

Construction

The first thing to bear in mind is that you will need nearly all of the parts to hand to build it because, unlike the main model that's built from numbered bags, to build this you need to open all of bags #2 - #8 and sort the parts before you start. Consequently you'll need a very large area to work on.

Bags #1 don't need to be added to the pile because they are for the mine truck, which is built identically to that for the BWE. I didn't build a second one.

The model uses something like 75% of the parts and, crucially, the new parts in it are used only for cosmetic purposes so if you have enough Technic laying around you might be able build the actual mechanism without resorting to dismantling the BWE or buying another set.

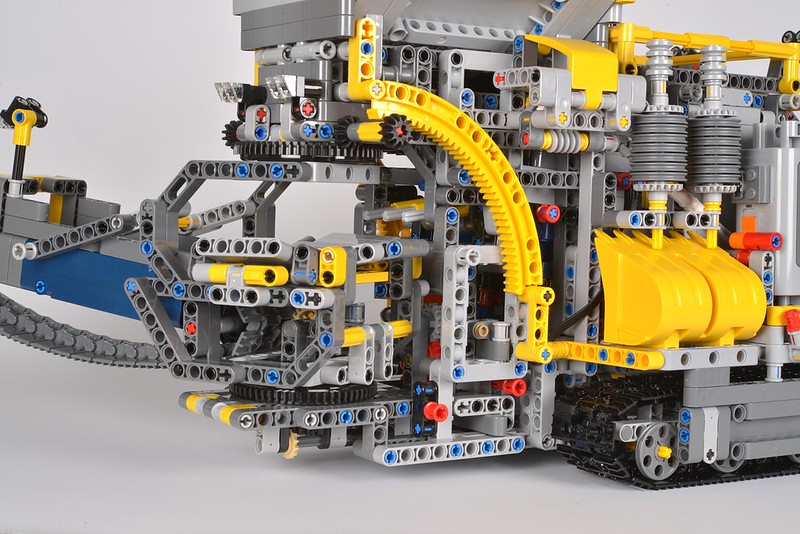

The completed model

The completed model looks impressive and suitably industrial. Gearboxes allow the single XL motor to propel the machine back and forth or operate the grader. You can't do both at once.

The left-hand output conveyer in the image below can be raised and lowered using gears on the side, while the one on the right can be rotated about 180 degrees.

(Note: I took the pictures outside in the garden this morning so they have a nice 'warm' tone to them.)

A third conveyer sits at the bottom of the input chute. It moves much slower than the output belts.

This side of the machine is not shown in any official shots but I think it looks quite impressive: the battery box sits on one side while two exhaust stacks occupy the other.

This is the end that the large pieces come out of. The conveyer assembly has a large turntable top and bottom allowing it to be rotated by the black gears, or simply pushed round.

Operation

So, how does it work? Quite cleverly as it happens, but unfortunately the mechanism is buried deep inside the machine so is impossible to photograph without a major dismantling. (Yes, I should have photo'd it before finishing it, I know...)

Basically, as the conveyer moves an 'agitating plate' is raised when the 1x5 beams on the belt pass under its end, which then drops again once it has passed. This in turn causes three axles under the input chute, mounted at a slight angle and spaced to allow 1x1 rounds to pass through them but not the 2x2s, to move up and down/vibrate as well. The 2x2s travel on top of the axles to their exit on the left (in the photo below) while the 1x1 fall through to theirs, on the right. You can see the ends of the three axles in the picture above.

That's the theory anyway... It's a neat mechanism and it almost works. Generally, the 2x2s always exit the machine correctly but the 1x1s often don't.

There are a number of issues that cause this and other problems:

- Occasionally, 1x1s will exit with the 2x2s. It seems to happen if they are carried along inside on top of multiple 2x2s or land sideways on the three axles. If that happens they invariably drop into the depths of the mechanism rather than travel along the belt because it's not been designed to stop them doing so.

- As the 1x1s ride up the correct conveyer, if they are close to the edge they sometimes jam on the sides, and if they are standing upright they can get stuck right at the end, by the yellow beams. In both instances the machine grinds to a halt

- If 'rocks' are poured into the exit of the input chute rather than on its conveyer belt you end up with too many inside which can cause the agitating mechanism to fail to operate properly.

- The 1x1s often just sit on the agitating plate and sometimes never exit. This is because (a) they are not spherical and (b) the plate is not completely smooth, so depending on how they land, they don't always roll down it. The plate's up and down movement is not sufficient to encourage them to move!

After experimenting this morning, I found a simple fix for the latter problem which doesn't solve it fully but does improve things considerably:

Here's the end of the agitating plate. The black axle is raised and lowered as the beams on the belt pass underneath it. By adding the 1.5l tan pin to the middle hole of the beam, the axle is raised a bit more and, importantly, falls a bit further, which jolts the 1x1s into motion and generally causes the machine to operate a bit more smoothly.

Verdict

If the 'rocks' were LEGO footballs and 1x1 spheres (which don't exist) I am sure it would work perfectly, but as it is, yes, it works, but not without problems.

Nevertheless it's a very interesting machine to construct and operate and if you have the opportunity to build it for yourself I encourage you to so do. Perhaps you'll come up with some fixes for the other issues...

Thanks to Evvilspoon, who's also built it, for confirming that it was not just my model that had problems with the 1x1s.

Video review

This is definitely a model that benefits from a video review but they are thin on the ground on YouTube at the moment. If I wasn't hopeless with a video camera I would have had a go myself.

However, I did find this one by Desert Eagle LEGO Technic Creations this morning that shows how it works, and how it jams. It's in Russian with subtitles.

37 likes

19 comments on this article

Nice overview Huw! What size is it? Also, what does it look like alongside the BWE?

^^^ Dang! I forgot to mention about that, and it's important!

Unfortunately the chute is too high for the BWEs exit conveyor to feed into it if both are on level ground. Its edges are about 21cm from the ground; the bottom of the BWEs conveyer is about 18cm. Although few will be able to buy two of the set, I do think not making the two models compatible is a missed opportunity.

^^ I didn't really keep a tally because I built it whenever I had a spare 15 minutes over the weekend, but probably 4-5 hours.

^ It's 85cm long, 25cm high. Next time I have my large photo backdrop out I'll take a photo. of the two of them.

I was really looking forward to this set, but knowing that both models have their problems I may pass unless I can find a good discount on it.

Plus my backlog is rather large at the moment and I'm a slow builder as it is. I've spent about 5 hours now on the Volvo EW160E and I'm only as far as having the pneumatic hoses routed (which Huw's excellent review made me want to purchase).

@Matt89190 If you watch the video @6:04 he has all three from the BWE to the grader to the truck and you get a good size comparison.

@BombTec That's his own version though, not the official BWE (and it's sitting on a pile of books).

It occurs to me that some of the fun from the more advanced Technic sets actually comes from fixing problems with the initial design! If they were perfect to begin with, would they be as much fun? :)

Hi Huw, the operational problems sound very much like what we get in the quarry where I work, where we operate very similar mobile screening units. We load our machines with Volvo L350 Shovels, so I would be very interested in seeing the two models side by side for scale.

I think people forget this is lego, like the a model its not functional for rocks or hamsters. Still both models are a great technical excersise which proves what the brick can do.

^ I have visions of someone trying to put a hamster though it now! :O

Thank you so much for this extra effort! Sounds like a fascinating model, even a little more so because of the problems (which are, as George_Rossiter mentions, not confined to Lego models alone). I will have to think long and hard about this set; normally I don't bother with the super-large Technic models but this is very, very tempting. Will have to keep an eye on Brickset to see if anyone is dividing it up into small truck plus larger structure.

I don't really want to know how much does it take to disassemble the BWE.

what about Soccer balls, and Mixel eyeballs (technic/bionicle ball joint balls)... might work?

@Paperballpark: Just a matter of time before Sariel does his video review, so we shall see!

^^ The eyeballs are just very slightly too big. Sometimes they fall through, when their flat face is parallel to the axles, but usually they don't.

As someone that works in the mining industry I simply had to buy the BWE! I was very happy with the model and am looking forward for some free time to build this mobile screening plant.

From what I have seen so far the problems with the operation are mostly related to the size of the pieces (rocks). This type of equipment is not designed to screen rocks that are so closely related in size and shape. I mean, the rocks are way over scaled compared to the machine. I believe that if we manage to make the smaller "rocks" smaller, it should increase its efficiency.

It is also important to note that a real machine has a known loading rate that must be respected by the people operating it otherwise it will clogg and jam and it will be inoperable for many hours.

In summary, this machine needs some special care and attention, but so does the real thing.

What about using 1x1 round plates and/or tiles?

They'd just get lost in the bowels of the machine...

Here is Sariel's video review of the B model: https://www.youtube.com/watch?v=t4m-fHmW6Ro

I think I will be buying two BWE and having a version of both in operation, did watch a vid on youtube with both models working together, the guy removed half of the hopper on one side so the BWE could feed materials through ??, awesome reviews though many thanks, Vinny