The making of a minifig

Posted by Huw,

Among the resources shared by LEGO today to mark the minifigure's 40th birthday are photos of the moulds used for their manufacture and a video showing them being assembled and printed.

We tend to take them for granted but the video will give you a new appreciation for just how involved producing them is. The wall of parts shown towards the end is particularly interesting.

Assembly and printing

A fascinating video showing the component parts of the torso and legs being assembled and printed:

Moulds

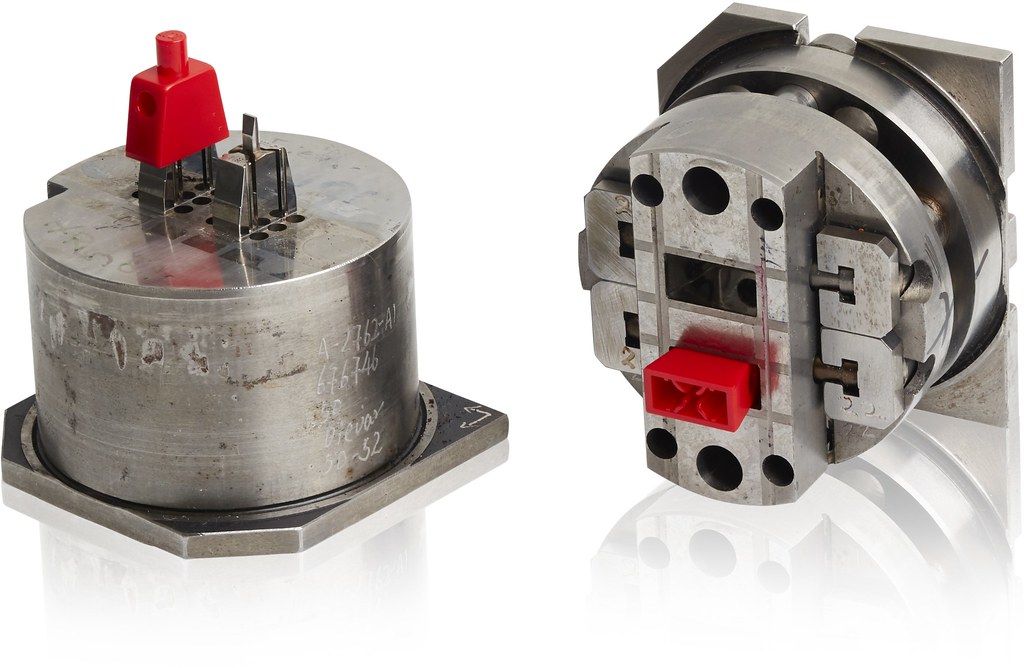

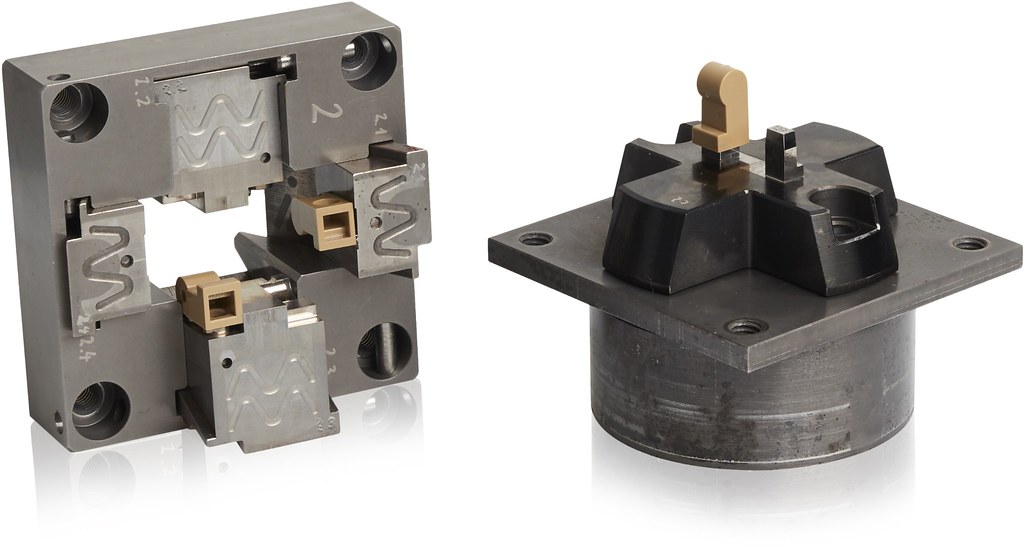

The basic minifig is assembled from nine pieces of plastic, all of which have to be moulded separately, of course. Here are photos of the moulds used:

152 likes

37 comments on this article

Very cool

Pretty cool. I sometimes wonder how they are made, and now i know.

Very interesting, I was curious about the force needed to add arms but it wasn't in the video. Did anyone else notice about 6:50 a hand didn't actually attach..... I assume there is a human at the end checking.... Makes then worth £3 ish now I suppose (collectable ones at least)

The vast majority of the plant machinery is provided by an Austrian company named ENGEL:

A Lego model of the injection moulding system:

https://www.nachrichten.at/nachrichten/wirtschaft/wirtschaftsraumooe/Fast-1600-Lego-Anlagen-aus-Schwertberg;art467,1357651,B

Those molds are almost "art pieces" , being able to produce again and again (and at such a fast cadence) perfect and similar parts that will so tightly connect to each other, even made decades ago, and fit with one manufactured yesterday. This is one of major Lego argument and force, that older parts are still usable today. Mold designers and manufacturers are also probably such a key factor in the process. Those molds are the true treasures of TLG...

Two questions:

- why is the pin of torse always colored? Is this like a sample for the prints?

- why does the leg part has very strange pins, more polygon shaped than round...

@Lego34s glad you spotted the missing hand too thought my eyes were playing tricks on me. I also would like to have seen how the arms (and legs) are attached.

Overall it's a good video that gave a glimpse at the world inside a Lego factory. I found it very interesting the way they vibrated the pieces on increasingly smaller ledges to get the parts lined up for the machines to grab. They maybe spent too much time on the printing process as printing a head/torso/leg is very much the same. However it may be that some of the more specialised work is done by more secretive machines.

@merman: I think the torso pin is coloured so the machinery can see which way the torso is facing before the arms go in. I don't know about the shape of the leg pins but I guess it's the best compromise between strength and friction.

I've always wondered why LEGO don't own the company that makes the tooling? Either by purchasing Engel or creating their own tooling manufacturing company.

@CalumHeath why would Lego invest time and money into such a different business which is industrial tool making? They had let loose the Legoland business because they couldn't handle it as it was so different from toy making and selling.

I now know about the birds and the bees Lego style.

But... But... I was told the STORK brought new minifigs into the world! Is that really how new Lego people are made? Ew gross!

Absolutely incredible!

I MOC'd this set a few years back...one of my favorites!

https://brickset.com/sets/4000001-1/Moulding-Machines

Not to downplay Lego’s capabilities but, coming from the plastic injection moulding business, I do want to provide some more context. First of all, plastic injection moulding is a high precision manufacturing process by definition. It’s not that the moulds Lego uses are that special. However, factors that influence (e)quality of parts are the composition of the base polymer, handling material and processing conditions. Obviously, the quality department is also a factor. All of this becomes more challenging when you’re, like Lego, producing parts in production facilities in different parts of the world and (possibly/probably) using granulate from different material suppliers). The fact that some people can identify Lego parts made in China proves this point.

@CalumHeath: Engel is a manufacturer of injection moulding machines; however, the moulds used on the machines are made by other companies (it could be that Lego do that in-house, I’m sure someone here can confirm/debunk). Out of curiosity I looked on Engel’s website: apparently, they also supply machines to Playmobil.

In the previous article I read that “…the minifigure head mould construction has improved from an initial eight elements per 9,8 sec. to 128 elements per 14.7 sec. today!”. Seeing the photo of the 8-cavity head mould here, makes me wonder if these days they use a 128-cavity mould… I doubt it, it’s probably the result of multiple machines moulding simultaneously.

Man the double clink when those legs are landing in the bin is so satisfying! (Although I don't believe it's the legs themselves making it.)

Marvelous, this is why Ideas specifically states no new molds must be suggested when submitting projects.

Quite an operation! Crazy what we do for toys.

This reminds me of when I was a kid--I'd assemble my minifigs and I only had to the count of five (from the moment i picked up the two pieces) to put the air tanks on, and then another count to five for the head, and another for the helmet. Otherwise the poor spaceman would suffocate for lack of air in space!

Through the many years, I never lost even one. Though sometimes I had to slow my count down a bit...

Cool, the video is from Czech Republic, Kladno factory.

"I wonder how old the machines are. We know from Chinese produced torso assemblies that they can be printed without the neck paint, so presumably there they are printed then the arms put on by the same machine / process flow. Whereas the picture of those blue printed but armless torsos in a big pile indicate that this video was done where they still do it the old way."

I assume TLG want ALL prints to be on the right surface - perhaps the Chinese just want to have most of the prints on the right surface...

I am an engineer in Kansas. I've designed a lot of plastic parts in my life (probably 130 or more). I am also a very big fan of Lego and it was pretty cool to get to see images of a tool that made these parts. I would imagine they would be using a much larger tool these days with multiple cavities to keep the part cost down. That would all be proprietary information, but I wouldn't doubt if some tools had cavity counts up in 100's. The problem is that the move cavities you have the more potential for quality issues and we always numbered our tool cavities so that you can trace the part back to the cavity it came out of. I don't recall seeing cavity numbers on these parts. Also having multiple tools making the same parts could be hard to keep track of. It just makes me wonder how they do this.

Wow, amazing to see all that moulds close up^^

I like how you can clearly see the element ID '381401' printed on that big box in the beginning xD

From one of the photos it's fairly easy to see that the 3 different torso variants (1978-1980: completely hollow, 1980-1997: small 'teeth' and post 1997: full cross supports) might actually come from the exact same mould that simply was modified by cutting the cavities in there. Maybe that's the reason why the white torso still uses the traditional 6-digit element ID despite being altered after the system change?

@merman.

the neck is painted to add friction. It makes taking off hair and hat pieces easier. Try with one where the paint wasn't there (like on my Edna Crabapple) or where it has been worn off.

That is why The LEGO Group should start making/selling monochorme minifigures in *all* colors! Cheapest way:

-for TLG to make lots of money (no additional processing (printing) required)

- buyers (us) would have access to reasonable priced minifigs

Fascinating video.

Happy 40th Birthday LEGO Minifigure!

Wow. If there's one thing off just slightly they'd end up with a bunch of messed up figures. How would you like to be the one responsible for left arms going where there right ones are supposed to be? Haha.

RE: Cavity Numbers

I don't have a minifig with me, but the cavity numbers are on the underside of most bricks.

On a 2x4 plate I can see up to '41-96', but whether there are actually 96 2x4s on an alloy mould... seeing the size of the machine in Legoland Germany and the factory in Hungary, I would think they don't do that many bricks per pressing.

@iwantbricks As far as I know they still have low cavity counts, nothing like the 100 you mention.

Each part does carry a mould number and cavity number. Hard to find on minifig pieces but have a look underneath a tile and you'll find a code like 08-03; mould 8, cavity 3.

@redbeardlegoman

Bang on... that little dot of paint makes all the difference when you're trying to get the helmet off a spaceman, and there's no way to get leverage otherwise. Although, you did also sometimes have to take the helmet off altogether, to turn the face, and then replace the helmet... which is why the old style helmets used to break at the seam on the chin-guard so much. Too much handling with no supporting head underneath.

Fascinating....gauntlet's been thrown down...come on,Lepin,show us your slapdash operation!

A Lego book about minifigures stated that the printing on the torso head pin is for printing the correct print on the correct side of the torso and putting the arms in with the correct orientation.

@BeaR the Builder Yeah.. I was wondering about plastic or granulate as you say. For some year I can tell some figures have different plastic. I wondered if that is just me feel or not. Typical polybag miniseries are from China I think and there is diffence. Even in movability. When I buy some set figures have hands and legs have more rigidity. But polybags minifigures series have legs and hands loosely. Sometime even my 20 yrs old figures from childhood have more legs rigidity than those new ones.

In case it wasn’t mentioned already, the print on the neck of the torso is for the sensor to line up the correct side for printing. Really enjoyed the video.

@redbeardlegoman:

That theory falls apart the instant you remember that unprinted torsos have unprinted necks. Given that the whole point of the LEGO System of Play is to make everything interchangeable, there's no reason to assume that a Classic Space helmet won't get added to a head that's attached to an unprinted torso, in which case there would be no added layer of paint to increase friction. That's a beneficial side effect, but the primary reason is for making sure the torso is facing the correct way when the arms get snapped on. The splotch is always the same color as some other layer of the torso print, so it's easy to apply alongside the torso printing process. The torsos get dumped into a bin before the arms are added, though, so they need to be able to reorient them so the arms will be correct.

@thor96

To ensure continuity of business. If the tooling company went out of business, or were bought by a rival of LEGO, LEGO would be screwed.

Also, I understand you don't know how business works but when you buy a company, the staff who know what they are doing usually come with it. Why would LEGO need to learn about tooling if they've just bought a tooling company? You can own a company and leave the running of it to people who know what they are doing.

(I have time on my hands)

Engel have a turnover of 1.5bn Euros, and staff of 6,600. Lego have income of 35bn dkk (4.7bn Euros) and 17,000 staff, so I guess Lego are about 3 times as big.

It would be a bold move to try and buy Engel. Also, Engel are family owned, and I guess as long as they are very profitable then the family would probably not be interested in selling. (I don't speak from experience ;-) )

Edit - From their pictures, it looks like they mould for Playmobil, and there are also pics that look a bit like megablocks...