Can you build the impossible?

Posted by Huw,

This article has been contributed by Duncan Bramley:

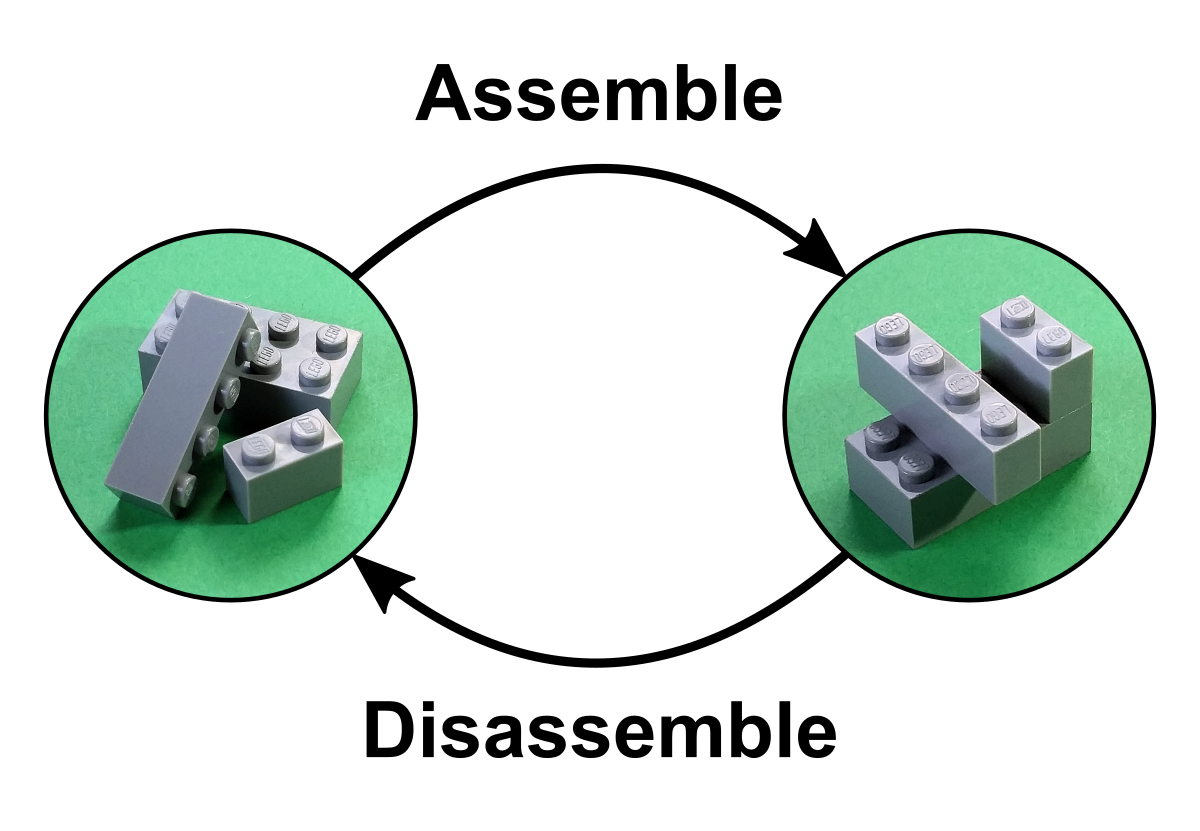

Use of LEGO involves assembly and disassembly, but what happens when either or both of these processes are not possible?

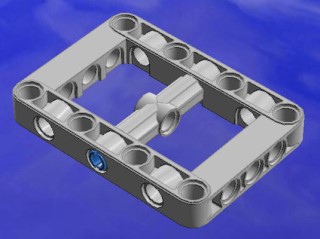

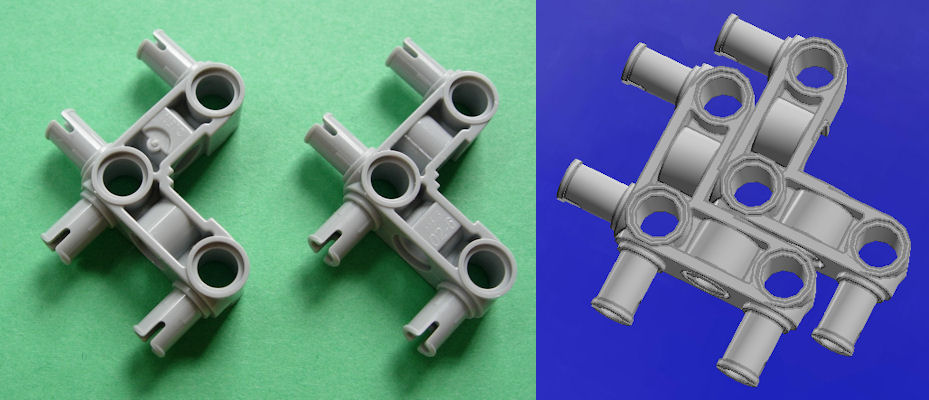

The Technic 5x7 frame provides ample opportunities to put pieces together in a way that they can't be disassembled and in this article I examine four types of LEGO construction that contain it, and invite you to solve a puzzle.

4 types of LEGO construction can be defined:

- 0: Can be assembled and disassembled.

- 1: Can be assembled but cannot be disassembled.

- 2: Cannot be assembled but can be disassembled.

- 3: Cannot be assembled or disassembled.

Type 0 — can be assembled and disassembled

This is clearly what is desirable and almost always achieved, no examples required.

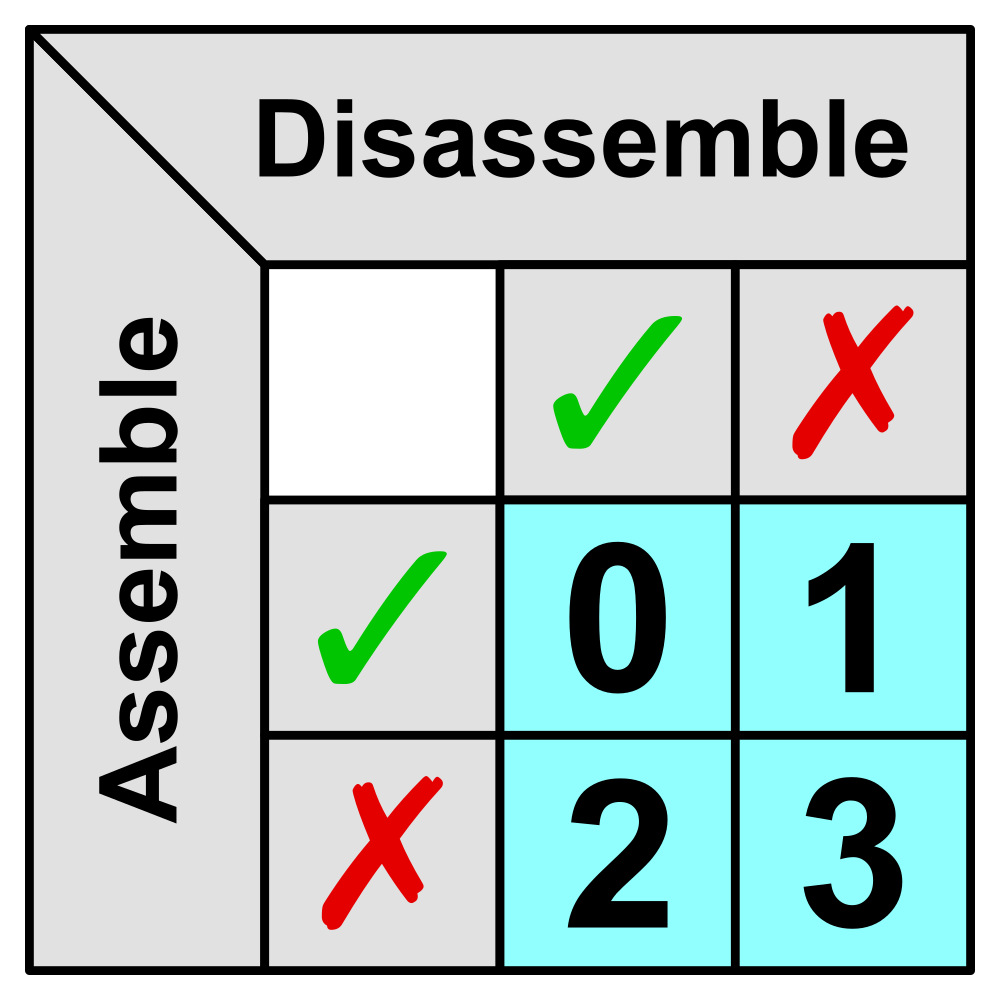

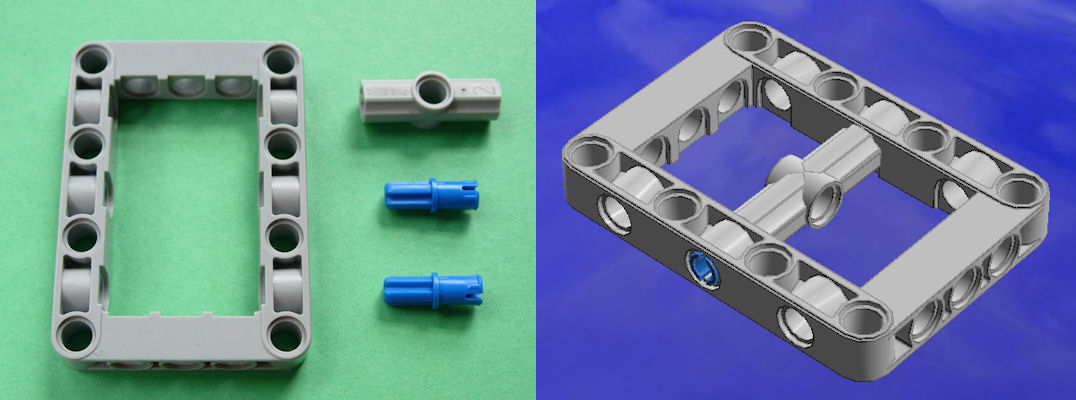

Type 3 — cannot be assembled or disassembled

Despite the fact that these cannot be disassembled, they are safe since they cannot be assembled in the first place:

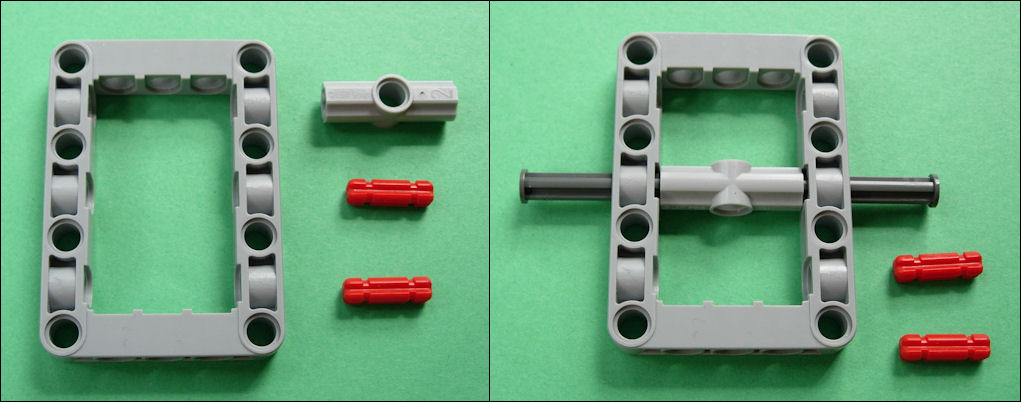

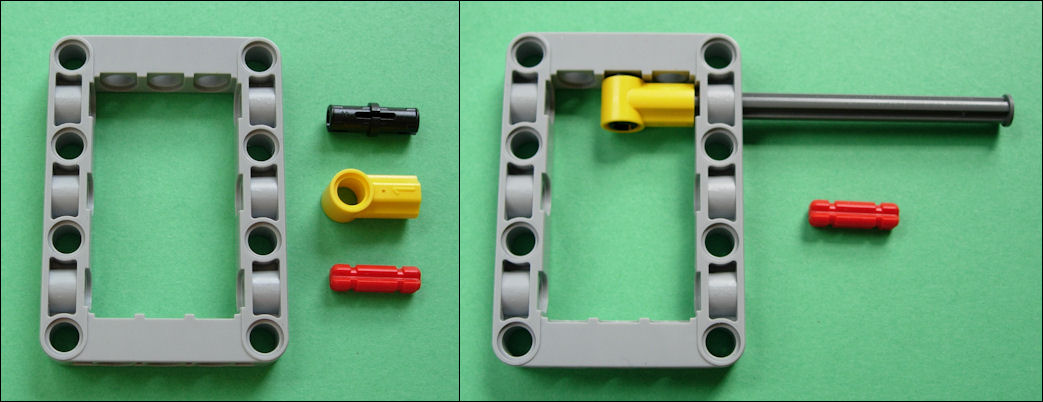

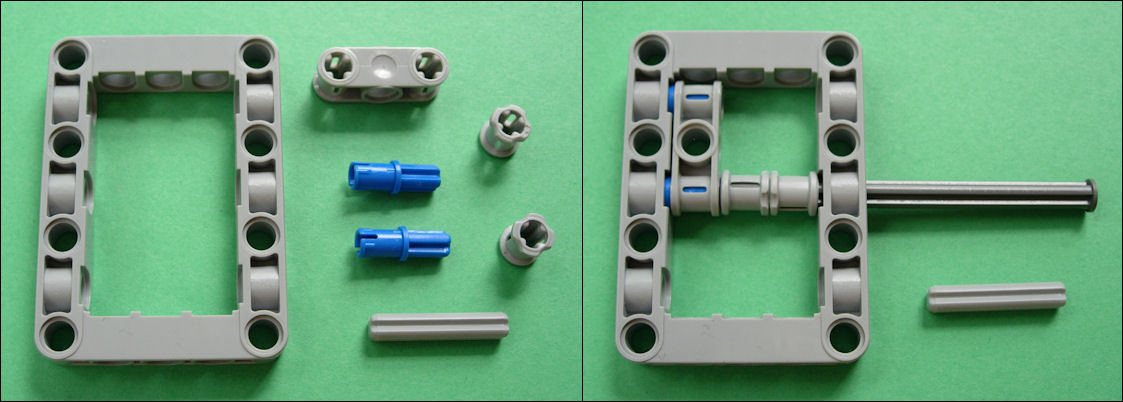

Type 1 — can be assembled but cannot be disassembled

These are a problem, but fortunately they rarely occur in practice:

(in the right-hand image of each example the shorter axle(s) to be used rather than the longer axle(s) shown)

Type 2 — cannot be assembled but can be disassembled

These are very safe since they cannot be assembled, but if such a construction did exist it could be disassembled!

The challenge is to find a type 2 construction -- can you come up with something that (seemingly) can't be constructed, but can be taken apart? Disassembly should be by hand with the optional use of a brick separator tool.

There is a solution and I will present it to you next weekend.

185 likes

94 comments on this article

Interesting, I'd never considered any of this! Good luck on finding type 2. From the initial description, I was thinking of parts like the coins or wands which you have to snap off the plastic core, but clearly that's not what you're looking for.

Another infamous example of a type 1 is, of course, putting a transparent 1x1 cone over a lightsaber blade

@magmafrost that is so true! I think I still have a construct of that somewhere....

I see 2 mating llamas in type 3, is it just me? ;)

@sid3windr said:

"I see 2 mating llamas in type 3, is it just me? ;)"

Wish you hadn't said that... now I can't un-see it! :D

Interesting article, thanks Duncan!

You have incorrectly categorised the first two examples of type 1 - although admittedly it is very hard, it is theoretically possible to separate these! With a pair of unfolded paperclips (or some other hard, thin material that is not TOO flexible, or maybe even a specially designed tool) you can try and reach into the four empty corners of the pinhole the axle resides in, and "pincer it" through the ridges on the 2-length axle in red, which can then be used as leverage to attempt to remove them. A friend of mine managed to seperate 41672, 32039 and a 2-length axle (connected at top left of the Bricklink image preview for the first part) using a similar method of catching the ridges in the axle through the relief holes.

Since there are no ridges in the 3-length axle, the third example in Type 1 is definitely lethal to the parts involved as expected and construction is truly impossible to seperate without part breakage.

^ Theoretically possible, but not very practical and certainly not without non-LEGO tools.

A 3l axle can be dragged out with a pair of thin-nosed pliers, albeit with damage to it.

a type 2 construction, rationnally, cannot exist, because assembly would be reversing the order of dissasembly

A type 2 could be those special pieces, like the wands or the old coin pieces, that is molded together and you have to snap them off a center piece. Once they are seperared you cannot put them together again

@toastergrl

Technically, The third example is also deconstructable by using small sturdy pincers to pull out the axle bar, because it leaves gaps between itself and the round hole it is placed in. Same goes for the blue pins, i Have used pincers to pull out these kind of pins with succes.

I love it. So puzzling, these pictures are quite magnetic to me.

I once put four ratcheted joints with bar sized holes together around the four pronged apparatus puns on the back of doc ock and then proceeded to put a spring loaded shooter through the center. It was a nightmare to get off. Also, would the steering wheel work for number 2?

Oh man, quite the challenge! I don’t think I can answer. However, this brings back torturous memories from the 80s and ruining countless technic pins!

@XcrismonP

True, but that can hardly be considered as "assembling" or "disassembling"

For type 2, what about a stud shooter trigger into a stud shooter? I've never ben able to separate one!

@Tuun said:

"a type 2 construction, rationnally, cannot exist, because assembly would be reversing the order of dissasembly"

Exactly. Something that can be disassembled can by definition always be assembled. Therefor a type 2 in the true sense can't exist. I am very curious to see your solution.

@toastergrl re:

"Since there are no ridges in the 3-length axle, the third example in Type 1 is definitely lethal to the parts involved as expected and construction is truly impossible to seperate without part breakage."

I wouldn't say so for certain. I would fill silicone (the kind you use in DIY projects as a sealant) into the hole. After it has dried it is usually powerful enough to pull out anything that is stuck in the hole (like the 3L Axle) but easy enough to clear off later without damaging the part.

One thing I did once was put four 1x2 click-hinge bricks (click-hinges on both sides, to be clear) together in a circle.

I THINK I got this apart just recently, but it was very, VERY difficult to do so.

You could tessellate a combination of tiled bricks and lock them with a single tiled piece. No studs or connection points but locked by geometry but can be disassembled by removing the locking brick?

I decided to sell Kylo Ren’s Shuttle (75256) and the disassembly of the mechanism in the body of the spacecraft was nearly impossible! Seriously, that set was meant to never be disassembled. I was shocked, and wonder if LEGO made an error, since being the ability to reassemble LEGO parts seems to be a core promise...

I am actually waiting for the answers next time, on Brickset....

hmm. A brand new minifigure torso? It requires no initial assembly, but can be disassembled (the hands and arms can be removed) and then reassembled again.

My personal experience with a type 1 (almost!) was taking a 2x2 plate with an axle that would normally be connected to the wheel of a car, as seen in many city sets, then placing that axle in the hollow stud of a 1x4 brick with studs on the side. Because the axle could not be compressed again from within the brick, the only way to remove it was brute force, which eventually worked but caused damage to the axle, rendering it unusable. Very interesting article!

Are there any pieces with a ratchet or barb that makes it impossible to insert them into another piece the wrong way, but if they had somehow been inserted the wrong way would allow them to be pulled out in the other direction?

Type 1: Once I got the set 5955 , I didn't like the colorpattern legs of the two dinosaurs (stegosaurus and triceratops). I tried to disassemble both legpieces and swap them. Didn't succeed. Those parts are clicked together in a way so that I was afraid of messing it up.

For now, I got used to the odd colors.

Edit: Also.. Do stickers count as type 1?

Before the separator, every plate-on-plate assembly was basically a type 2...

The firing mechanism of set 8097 (Slave I) is a type 1 construction. Very annoying...

Type 2 sounds a paradox. If it cannot be assembled, their is nothing to disassemble, so "being able to be disassembled" cannot be interpreted. Or am I missing something?

Wouldn't type 2 just be a broken Minifigure with arms off? If the arms are already disassembled due to cracked in half torsos you can always reassemble them on a different torso. Or am I missing something here?

A type 2 construction would be a 32 cm piece of string threaded inside a 30 cm piece of pneumatic tubing. Easy to disassemble (just pull on either end), but impossible to "build", without using any non-LEGO tools.

The simplest way to satisfy type 2 in my mind is just a construction of any two non-real elements. For instance, two 2x2 plates in chrome silver... They can’t be assembled due to the fact that they don’t exist, but should you happen upon two of them stuck together, they could be easily separated!

A plausible type 2 scenario could exist depending on your definition of disassembly.

Consider any enclosed technic square piece like the one shown or the old 4x6 brick, etc.

Two of those connected like chain links inside one another and attached via a technic pin is impossible to assemble as it would require parts being broken apart or otherwise passing through another part.

But that assembly can be *technically* diassembled, the pin holding them together removed and both loops freefloating though caught inside each other. They're not connected so in theory they're not assembled.

Easy to "disassemble", impossible to "assemble". But only with a few asterisks as the assembly and disassembly are not equivalent.

If it cannot be assembled, then it cannot be disassembled, because it doesn't exist in the first place.

@magmafrost:

Those are difficult, but not impossible, to disassemble. You usually can't pull the bar free, but if you're careful enough, and strong enough, you can force the cone down over another bar to shove the lightsaber blade free.

@toastergrl:

No, the third Type 1 is definitely harder, but still not truly impossible. Since it is a pin hole, and not an axle hole, it's possible to grip one of the ridges on the 3 axle with a sufficiently narrow needlenose pliers. There _are_, however, some constructions where a grooved 2 axle can be removed while a smooth 2 axle is impossible to remove without destroying it. Some axle holes have an expansion slot on one side, so that instead of looking like a "+", they look more like a cross. In that case, the slot offers access to hook the grooved 2 axle, but not enough to use pliers on a smooth axle.

@Huw:

The hand/brick separator restriction was only mentioned in relation to the Type 2 challenge. No restrictions were stated regarding Type 1 constructions.

@XcrismonP:

Since they start out as a single part, I wouldn't consider that to be a legitimate response. Besides, if that's fair, you set a few brick separators on fire*, you can use them to heat up the sprue tips enough to fuse the pieces back together, which would fit within the imposed restrictions.

@Robot99:

That's easy. Just pick two opposite corners and squeeze. Leverage will take care of the rest.

@SirZed:

I can think of a way to "assemble" those. Get the string wet, stretch it taut, freeze it, and then stick it through the hose like a giant needle.

* No brick separators were harmed in the typing of this description.

Ooh. Philosophical debates about lego. My favorite.

Technically any one piece can be disassembled but not reassembled by simply breaking it, but I’m not sure that’s what the challenge had in mind.

I dunno, some of the "Double snap with hole" (part 6055630) can be almost impossible to remove for anyone who's ever tried to dismantle the UCS Falcon. Many snap into pieces like the frame from this articel, where there's no convenient place to put an axle to pop them out from the back. They have no groove (unlike tiles) for you to wedge something under--and often there are pieces on either side that won't let your fingers get a good grip on them since the're only two plates (without a stud on top) tall.

Type 2 originally would be some part, one part in first place, that practicaly, you would brake in two, or more pieces, and use all pieces as Lego pieces.

On the topic of things un-dissassemblable: Has anybody else built the new UCS A-Wing? Was I the only one that grimaced at the instruction to insert that pearl gold 3L bar to hold the l/r wing assembly? I was tempted to tear it down immediately just to see how it would possibly be retreived.

This probably doesn't count as a type 2 construction, but it reminds me of the times when LEGO sets gave you lengths of pneumatic tubes or string and the instructions wanted you to cut them to size with a pair of scissors. You can't uncut pnumatic tubes or string to make them longer.

@PurpleDave

You sure about that? Don't the bottom corners of the bricks block that kind of action?

To be clear, I was talking about this:

https://brickset.com/parts/4251959/brick-1x2-fric-stub-fork-vert

While building the UCS A-wing today, I very nearly inserted an axle with flat end into the wrong hole (I was one hole out). I realised just in time, but if I had done so I would have ended up in an "impossible to disassemble" situation. So a very timely article from my perspective.

Back in my day, we didn’t have brick separators. If bricks were stuck together, we’d have to try to stick them to larger bricks for leverage to separate, use a knife to pry them apart, or live with the connection permanently.

I still view brick separators as cheating.

I just took a good look at the type 3 images. My brain now hurts...

@Huw i think the lockdown may have started to get to you.....

You lost me many words ago, im stuck on the logic of taking something apart that you cant put together........ but worse than that its just brought back a painful memory of building the big R2D2.... for which for some reason I did one bag every Sunday, about 8 weeks in I put the wrong axle in the right hole and ended up spending an hour pulling it all apart to get it back out. Had to go back about 30 pages........Stressful ....very. Although my other half told me..... "well at least you get more time doing Lego". Non FOLs eh.........

What is glued?probably light brick?well,once you disassemble something glued,it cannot be put back together...

@chrisalddin said:

" @Huw i think the lockdown may have started to get to you....."

Huw didn’t write it. A contributor named Duncan Bradley wrote it.

@SirBrickalotOfLego said:

"For type 2, what about a stud shooter trigger into a stud shooter? I've never ben able to separate one!"

I managed to remove all the triggers from mine to prevent accidental firing but I had to use a thin nail type thing to reach down the barrel and ping it upward, but it is not a "Lego" solution.

For type 2, what if you untie a net piece (23206)? surely you could just tie it back up, but it won't be exactly the same way that it came?

My favorite Type 3 Construction is what I refer to as 'The Toilet Paper' (apt times, eh?): you take a 48336, Plate, Modified 1 x 2 with Handle on Side - Closed Ends and a 3062b, 1x1 Brick- Round (preferably in white), and place the round brick on the bar like a roll of Toilet Paper! It is technically possible to easily do in Lego Digital Designer as it doesn't sense a collision (LDRAW based programs and other things like Mecabricks can achieve the same as they have no collision, although LDD is a bit more realistic in how it processes part collisions- sometimes).

(Sorry for the possible dupe post my first one seems to have glitched.)

I have another one.

Required:

Small Technic Gear

Black Axle Pin (2 Studs)

Rahkshi Gearbox.

Insert the Gear into its slot, put 2 Stud axle in. Impossible to get out with any lego piece.

It was stuck in there for atleast 10 years, until I used some really small metal tools to push it out the other way a few weeks ago.

Type 2 is the best joke of the evening.

https://imgur.com/xSl4qV4

I don't know if this really counts, but I managed to "assemble" an example of my previous post in LDD and screencapped it. Impossible to actually assemble, easy to "disassemble".

@magmafrost said:

"Another infamous example of a type 1 is, of course, putting a transparent 1x1 cone over a lightsaber blade"

I had a couple of these for years. One day I tried pulling them apart and they just did. Still not sure what happened.

something happended to my first post..

For type 2: pneumatic hose going throught 2x4 brick with holes (3709a) in a way that it

comes out from hole right next input hole, doing 180 degree turn inside.

Disassembly just by pulling hose out.

Assemble would require hose magically make turn inside the brick to come out in opposite direction instead of going straight throught.

@krysto2002 said:

" https://imgur.com/xSl4qV4

I don't know if this really counts, but I managed to "assemble" an example of my previous post in LDD and screencapped it. Impossible to actually assemble, easy to "disassemble"."

Can you actually disassemble that though? I'm pretty sure the two technic frames are locked within each other, even if the aren't attached to each other with the pins.

Still, pretty cool (and mind-bending) example nonetheless.

@Robot99 said:

" @krysto2002 said:

" https://imgur.com/xSl4qV4

I don't know if this really counts, but I managed to "assemble" an example of my previous post in LDD and screencapped it. Impossible to actually assemble, easy to "disassemble"."

Can you actually disassemble that though? I'm pretty sure the two technic frames are locked within each other, even if the aren't attached to each other with the pins.

Still, pretty cool (and mind-bending) example nonetheless."

My previous post explains that a little more thoroughly.

Yeah it the assembly and disassembly come with several asterisks apiece:

It's impossible to assemble, yes.

But it's also impossible to fully disassemble. Yes the parts can be separated to some extent one could call disassembled, but if you approach them from that metric they can also be reassembled as well.

So it's not *really* a proper example, but it is still a silly thing that can be accomplished in LDD.

My guess is disassembly of type 2 would have to result in increase of entropy somehow.

For a type 2, I could imagine the existence of a spring-loaded ratchet system so that when you pull a piece out of an assembly, it cannot be inserted back in. Just as you can't pull the hook on the Landrover winch unless you also pull the release lever, you could not pull the spring-loaded piece out of the way to insert the other piece because there would be no rachet release lever. Think something like a grenade pin. The question is, how to design it so that access to the rachet is unavailable during the assembly process.

Another might be to have an axle with end-stop, penetrating an enclosed space with a gear on the far end of the axle. If the axle isn't long enough to push the gear against an obstruction at the far end of the enclosure, then you couldn't attach the gear to the axle to complete the assembly; the gear would always push out of the way. But if the gear were already attached to the axle, then you could easily pull the axle out. If you've ever tried to swap out a gear in the middle of a drive train on a build without tearing down the whole thing, you may have faced a situation somewhat like this.

Do I want to spend the time figuring either of these out in LDD? No. But I could see them being examples of this scenario.

Hi guys, just spent a good hour discussing this with a friend. Came up with something: https://imgur.com/a/wDTkYqs

@honzas3000 said:

"Hi guys, just spent a good hour discussing this with a friend. Came up with something: https://imgur.com/a/wDTkYqs"

Excellent! Very well done.

@honzas3000 said:

"Hi guys, just spent a good hour discussing this with a friend. Came up with something: https://imgur.com/a/wDTkYqs"

Hm! This seems like a winner to me!

My brain hurts even more than from the type 3 images...

@honzas3000 said:

"Hi guys, just spent a good hour discussing this with a friend. Came up with something: https://imgur.com/a/wDTkYqs"

That is just awesome! Love to see some variatons on that, or a whole other kind of assembling

That's a great example but it is actually impossible to build. The example Duncan has provided is seemingly impossible, but not totally. In other words, if you saw it constructed you would not know how it was built.

I think I might have to post it sooner than next weekend to put you all out of your misery. I'll do so tomorrow!

@Huw said:

"That's a great example but it is actually impossible to build. The example Duncan has provided is seemingly impossible, but not totally. In other words, if you saw it constructed you would not know how it was built.

I think I might have to post it sooner than next weekend to put you all out of your misery. I'll do so tomorrow!"

Hm? But weren't we looking for a kind if setup that, I quote, "cannot be assembled but can be disassembled"?

It seems that @wiztom and @honzas3000 beat me with some pretty cool solutions, but I may as well throw this out there. Here is my Type 2 solution:

https://imgur.com/a/5qRT1ny

As far as I can tell, it cannot be assembled. I even added in the yellow BIONICLE hand to lessen allegations that it could be possible-but-just-painful to assemble. Hopefully this checks out and I am correct!

@Futurism said:

"It seems that @wiztom and @honzas3000 beat me with some pretty cool solutions, but I may as well throw this out there. Here is my Type 2 solution:

https://imgur.com/a/5qRT1ny

As far as I can tell, it cannot be assembled. I even added in the yellow BIONICLE hand to lessen allegations that it could be possible-but-just-painful to assemble. Hopefully this checks out and I am correct!"

I just built this. Push the lightsaber in 3.5 studs, pull lightsaber out, grab axle-pin-pin by the edge dividing the axle and pin part, push all the way out. Insert lightsaber with 1/2 pin.

@honzas3000 said:

" @Futurism said:

"It seems that @wiztom and @honzas3000 beat me with some pretty cool solutions, but I may as well throw this out there. Here is my Type 2 solution:

https://imgur.com/a/5qRT1ny

As far as I can tell, it cannot be assembled. I even added in the yellow BIONICLE hand to lessen allegations that it could be possible-but-just-painful to assemble. Hopefully this checks out and I am correct!"

I just built this. Push the lightsaber in 3.5 studs, pull lightsaber out, grab axle-pin-pin by the edge dividing the axle and pin part, push all the way out. Insert lightsaber with 1/2 pin."

Ah well. Nice try though, @Futurism .

^ If https://imgur.com/a/5qRT1ny can be constructed, and I'm prepared to believe that it can, but will try it tomorrow, then that is a good solution and built using exactly the techniques we had in mind.

Is this a late April Fool?

@honzas3000 said:

" @Futurism said:

"It seems that @wiztom and @honzas3000 beat me with some pretty cool solutions, but I may as well throw this out there. Here is my Type 2 solution:

https://imgur.com/a/5qRT1ny

As far as I can tell, it cannot be assembled. I even added in the yellow BIONICLE hand to lessen allegations that it could be possible-but-just-painful to assemble. Hopefully this checks out and I am correct!"

I just built this. Push the lightsaber in 3.5 studs, pull lightsaber out, grab axle-pin-pin by the edge dividing the axle and pin part, push all the way out. Insert lightsaber with 1/2 pin."

Dang, that's what I get for not having the parts on-hand to test with, I guess. If I understand your solution correctly, is it because the "corners" circled in the image below could get pushed on by the lightsaber rod? I forgot the piece had those. In that case, would replacing with the piece on the right make it impossible to assemble? Or did I misinterpret your solution?

https://imgur.com/a/H4Khxzr

@Huw said:

"^ If https://imgur.com/a/5qRT1ny can be constructed, and I'm prepared to believe that it can, but will try it tomorrow, then that is a good solution and built using exactly the techniques we had in mind."

I was under the impression that we were trying to find an opposite of case 1 - something that can be disassembled, but not legally (without some extreme bending or whatever) assembled using hands, tools or any natural forces.

the lego dagger or wands how they come in the box

Something that 'supposedly' can't be assembled, but can be disassembled.

So, the example above, if valid, is tricky/not obvious how to build, but can be disassembled.

So, I dug up as many of the IRL pieces as I could, and I think I managed to complete the assembly that honzas3000 described. I think one peg replacement removes the ability to assemble the construction, however. Because this replacement peg has the cross axle for one of its halves, the lightsaber rod can no longer be pushed in far enough to hit the green piece. Hopefully this fixes my earlier solution?

https://imgur.com/a/oyBYoui

@Robot99:

Nope, that's exactly the part I was thinking you were referring to. I did just track down a set of four of these (turns out I don't have many loose ones) and built the assembly you described. And yeah, it's not as easy as I thought it would be, but in theory it should still work. The only question is if you can do it without injuring yourself or damaging the parts. But, if you label the four corners North, East, South, and West, applying sufficient pressure across the N/S corners should cause the bevels on at the E/W corners to act as fulcrums, and force the E/W corners to separate. It just apparently requires a considerable amount of force to pull this off.

@PDelahanty:

Brick separators have been around for three decades. At this point, they quite likely predate more elements than they followed.

@andyh1984:

I can't remember what I did (it might have involved a minifig crowbar?), but I know I've been able to remove the 15392 trigger from the 15392 stud shooter at least once, if that's what you're referring to. And if you just want to prevent accidental discharge, there's a stupidly simple trick. Press the trigger down as if to fire a 1x1 round plate, and plug any 1x1 part w/ hollow or recessed stud into the barrel. The tip of the trigger will fit inside the stud, where it won't be able to provide enough leverage to pop the part out.

@Nexus_Riles:

Collision detection is a mixed blessing. There are physically possible models that can't be assembled digitally with collision detection turned on. For instance, you can build a wall entirely out of 1x2 plates, and you can force that wall into a shallow curve because the actual parts leave a tiny gap between themselves. In a digital build, there's no gap between the parts that would allow this.

@Teriyaqi:

You can permanently deform certain types of plastic by leaving them assembled for long periods of time. A certain other brand that made its basic parts out of styrene instead of ABS famously had this problem. People found that certain connections fit so badly they'd almost require a hammer to assemble, but when they'd try to pick the model up years later it would just collapse into component parts because styrene is ABS without any of the rubberizing agents that allow it to spring back into shape when disassembled.

@wiztom:

There are other parts, like the minifig crowbar, that can be used to help feed the tip into that 90 degree bend, so while almost certainly excruciatingly difficult, I don't know that this would be flat-out impossible.

@TeraMedia:

Grenade pins (at least on US-style grenades) _can_ be reinserted. It's just ill-advised if you've also released the lever on the side allowing it to spring free.

@SideSwept:

If those are holes in the rounded ends of that part, then while nearly impossible, those people who like to build ships in bottles could potentially assemble one of these. Although if the eggshell pieces were opaque, that would certainly complicate things.

@Futurism:

There are several bar elements that provide a section of bar that's longer than 4L. In particular, 30219 gives you about 10L reach before you'd run into the hollow stud where the boom mounts. So you'd need a much bigger frame to build it in to make it truly impossible to assemble either your first or second attempts.

But with your last revision, I think you might have found one. Short of pulling on the green axle tip with needlenose pliers to get it far enough where you can use force against the flange, there's now no way to move that single piece into position. Everything else could be built exactly as shown.

@PurpleDave I love your comment about grenade pins! "ill-advised"! A little bit of understatement, there...

@PurpleDave

Yeah, that sounds more in line with my experience. I DID eventually get them apart, as stated earlier, but it took a lot of effort. No damage to the pieces (or myself!) though.

@Robot99:

I just got back to playing around with them again. I last clipped my fingernails a week ago, which makes them the ideal length for LEGO construction (short enough to be useful, but not long enough that you're likely to rip a chunk out of them). I was able to get one of the connections loose by pinching the ribbed fingers on one part between the nails on my thumb and middle finger, and just pulling really hard. I then reversed the assembly (studs towards the center), tried compressing opposite corners again, gave up, and used the same trick to open the assembly up again. So, while my original idea may not be as feasible as I once thought, it's definitely possible to disassemble them without tools. It's just not something they could ever expect kids to pull off.

But I _did_ just prove the theory is sound on my idea. There's a longer version of that part, with four studs instead of two. I just built the same construct using four of those. While I couldn't compress the smaller square enough even pressing palm-to-palm, I can do it with the longer parts using just my thumb, middle finger, and ring finger on one hand. The extra two studs of length greatly amplify the amount of leverage you get on the fulcrum points such that if they made a 3-stud version of the same part it would probably be possible to compress it open with great effort.

My marriage seems easier to disassemble than to assemble, haha!

A nice example of a construction that may be impossible to disassemble (from 3min) :

https://www.youtube.com/watch?v=H8z0f7kPQEw

A type 2 scenario I was thinking: not having room (with finger or a plate) to push a part on a technic plate (or equivalent), but be able to separate them by pushing an axle through the hole of the plate.

What about popping the plumes out of the container rings in old castle sets, or separating pirate gold coins from the single mold set of four with a shared middle chunk? Not quite in the spirit of the more complex logic puzzles I know, but can be disassembled and can't be assembled again.

(I always kept that big chunky middle gold piece as some enormously high value, yet to be refined nugget...)

One example of a Type 1- construction is the one between the old bionicle heads from 2001 and their brainstalk-/eyepiece

About type2:

I just remembered the spring-fitted parts from old LEGOLAND sets:

Forklift (615, https://brickset.com/sets/615-2/Forklift) and shovel from excavator (e.g. 689, https://brickset.com/sets/689-1/Grabber). The spring used to come off during play but was a pain to put back on. I thing I mostly used pair of pliers.

@Futurism said:

"So, I dug up as many of the IRL pieces as I could, and I think I managed to complete the assembly that honzas3000 described. I think one peg replacement removes the ability to assemble the construction, however. Because this replacement peg has the cross axle for one of its halves, the lightsaber rod can no longer be pushed in far enough to hit the green piece. Hopefully this fixes my earlier solution?

https://imgur.com/a/oyBYoui "

Nice, that actually makes it impossible to build without bending the parts (maybe using a pair of tweezers and pulling the pin somehow would make it possible)! I still managed to build it, though.

Type 2, second try:

Construct enclosed box from 5x7 technic frames (64179), 5 stacked on top of eachothers and 3 inserted vertically in the middle.

Then use 3L pins (like 32054) to connect all frames together, but magically inserting them from inside the box toward outside.

5 pins should keep box held together, 15 for maxing out one face.

Disassembly is simple by just poking pins in from outside into inside with help of axle and taking frames apart.

This could be constructed by using axis from opposite side of frame to push 3L pins to place but that side could be blocked with small pins (4275) from inside.

@swedishbrick said:

"One example of a Type 1- construction is the one between the old bionicle heads from 2001 and their brainstalk-/eyepiece"

Those actually can be dissembled without damaging them, although its not particularly easy to do

@honzas3000:

This could be built with a little phase-change trickery. If you place a 2x2-sized chunk of ice between the two 1/2 bushings inside the 4x6 technic box, the ice can hold one of the bushings in place after you assemble the two halves of the egg. If you use dry-ice, there won't even be any water leftover... though there might be some damage to the adjacent parts. I'm not sure what that low of a temperature will do to the plastic.

That's pretty much what I was proposing in my second idea - using an axle with an end-stop pushed into something without any reactive force - but you actually figured out how to do it. That's pretty cool.

@magmafrost:

Removing the eyes from the head does in fact damage them, but this doesn't become obvious until you've done it several times. Minifig arms/torso are the same way.

@magmafrost said:

"Another infamous example of a type 1 is, of course, putting a transparent 1x1 cone over a lightsaber blade"

So very true...

You are literally a hopeless LEGO noob if you actually put those two pieces together...

Maybe it's talking about minifigure legs where they come put together and you can take them apart? Or maybe minifigure arms? But I guess that you're not supposed to take those apart anyway... I guess you can always put them back together.

You'rs so right @magmafrost! I hate when I do that. I have to get pliers and it's really annoying

I agree with @SirBrickalotOfLego. I can't figure out how to separate those!

I submit that any Lego motor is a Type 2 construction: if you take it apart to its most fundamental components, you would not be able to put it back together again.

Also submit a Technic universal joint. If separated, you'd break it.